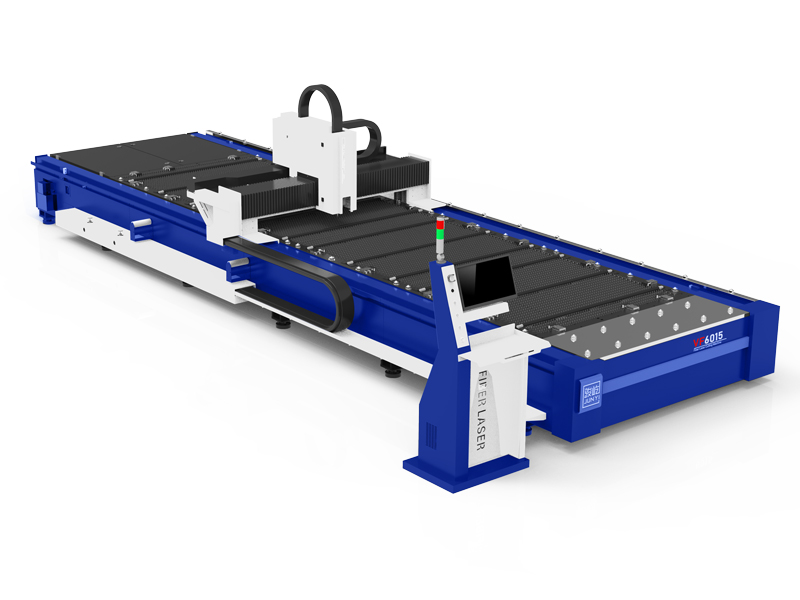

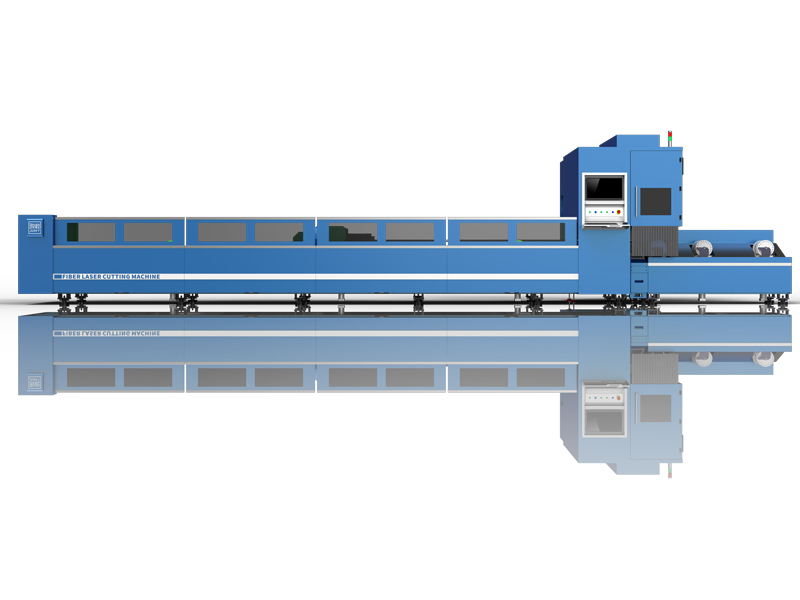

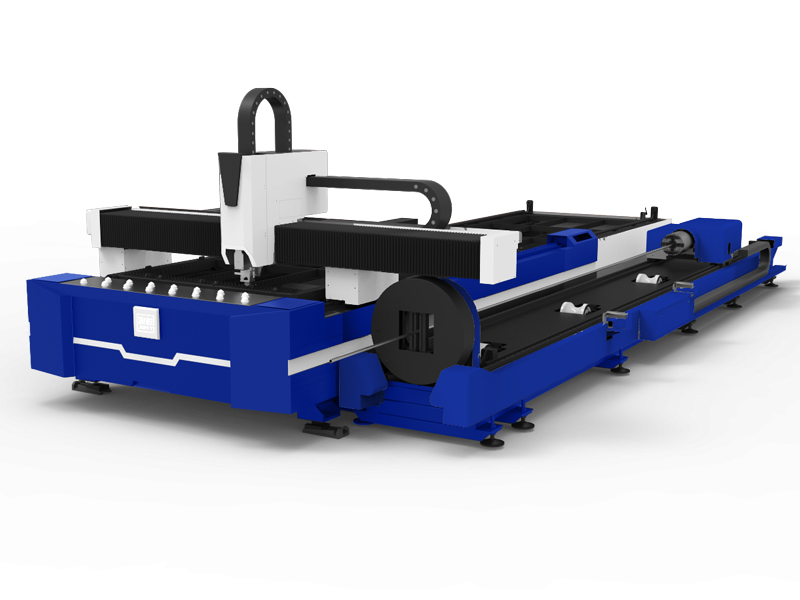

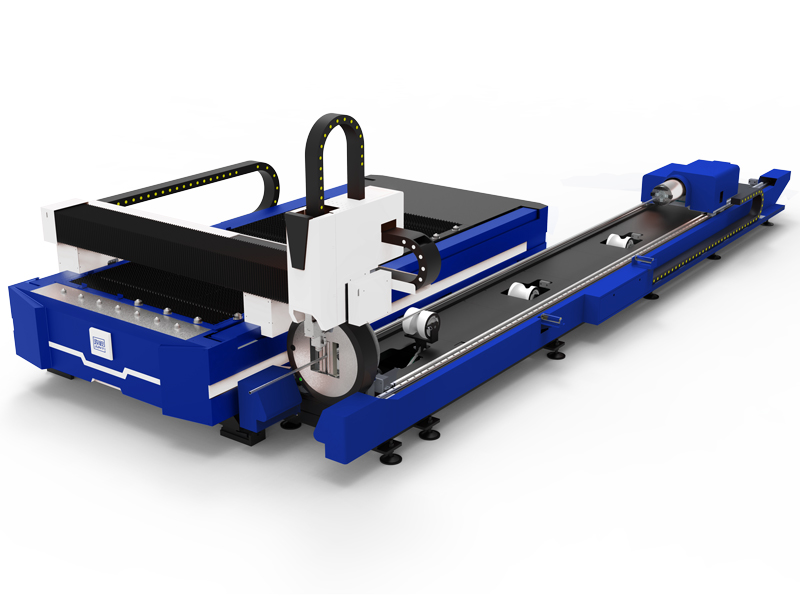

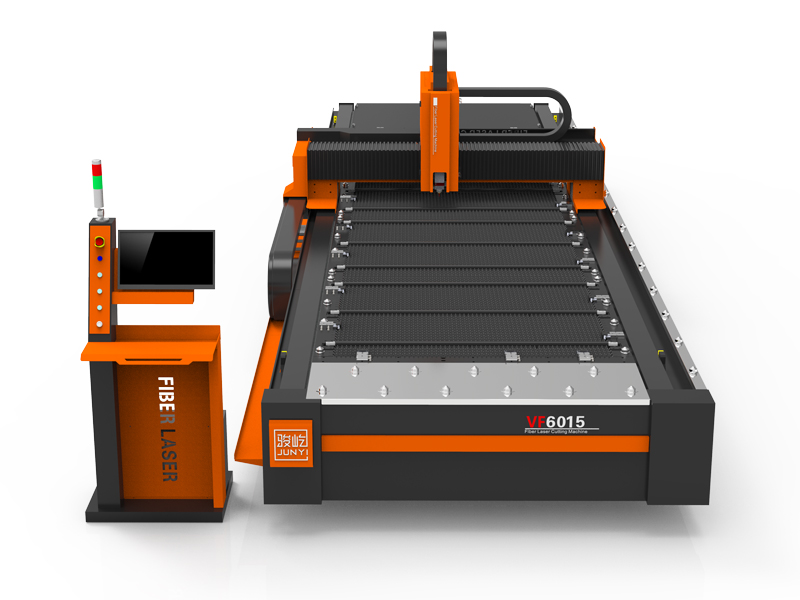

Upgraded 6 Meters Fiber Laser Cutter With The Newest Software

Video

Video

SPECIFICATIONS

Processing format (L*W) |

6000*1500mm |

Laser power |

1500-6000W |

X/Y axis positioning accuracy |

±0.03mm/m |

X/Y axis repeat positioning accuracy |

±0.03mm/m |

Maximum acceleration |

0.8G |

Maximum speed |

80m/min |

Power supply |

AC380V±5% 50/60Hz 3Phase |

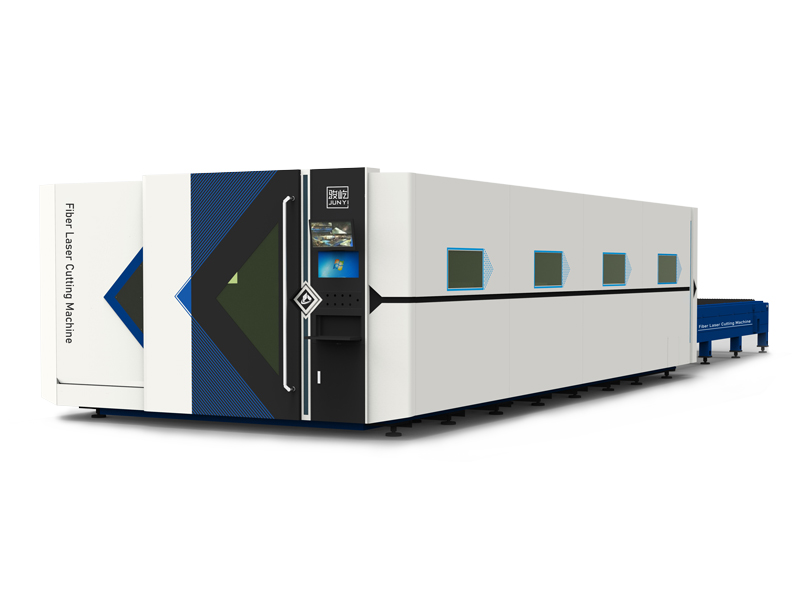

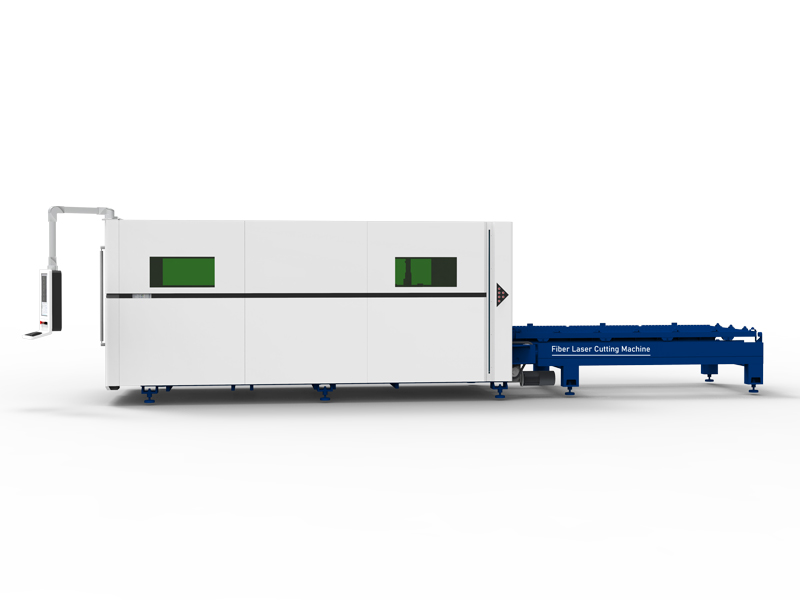

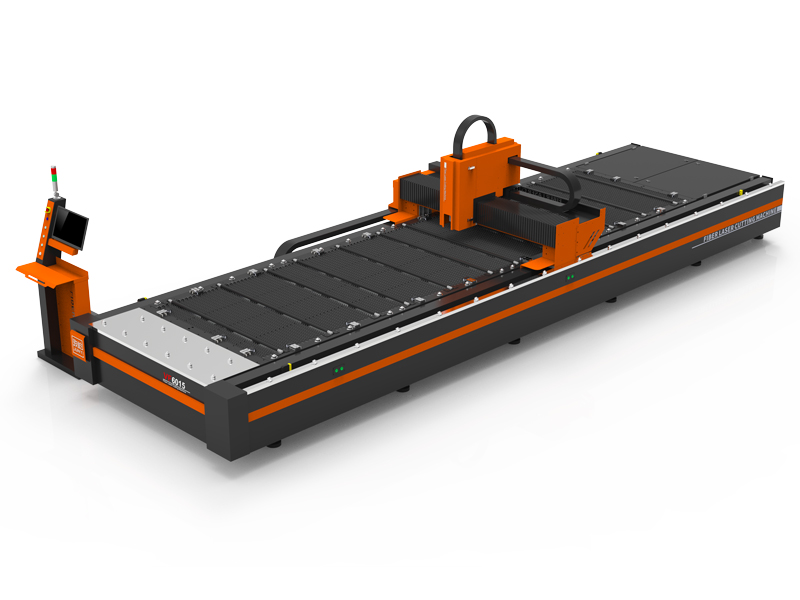

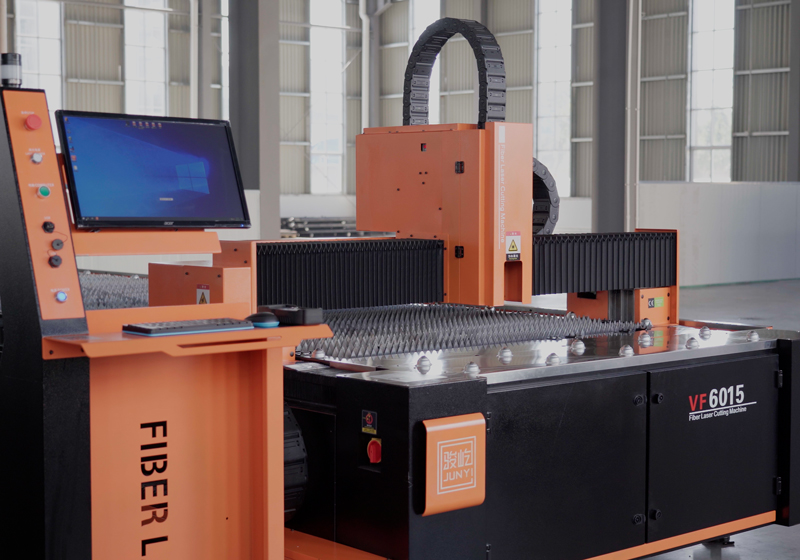

Efficiency is a top priority in the manufacturing industry, and this laser cutting machine delivers exceptional performance. Its impressive cutting speed allows for the quick completion of a large number of door panels, significantly improving production efficiency. With this machine, manufacturers can meet tight deadlines without compromising on quality.

Automation is another notable feature of this laser cutting machine. When paired with a computer control system, it can achieve a fully automated cutting process. This reduces the need for manual operations, streamlines production, and ensures consistently high quality.

PRODUCT ADVANTAGES

Larger cutting range

Higher production efficiency

Wider application fields

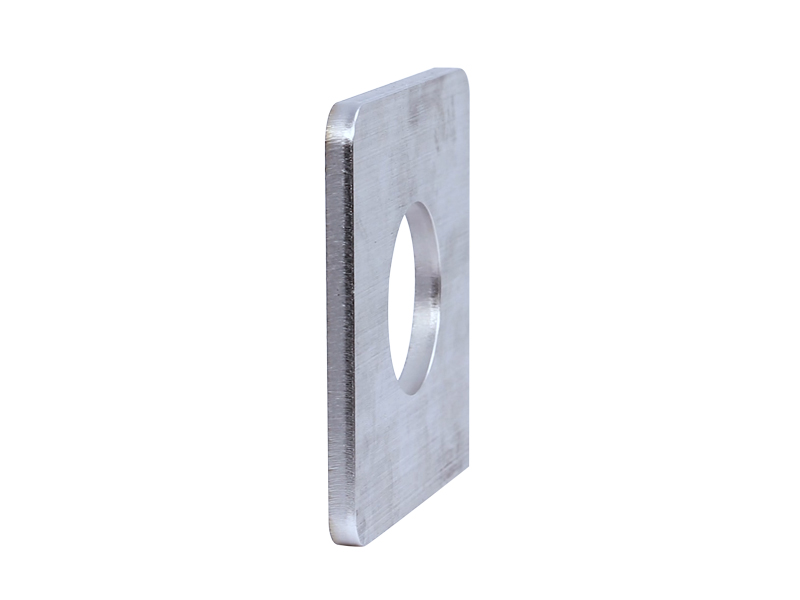

Higher precision and quality

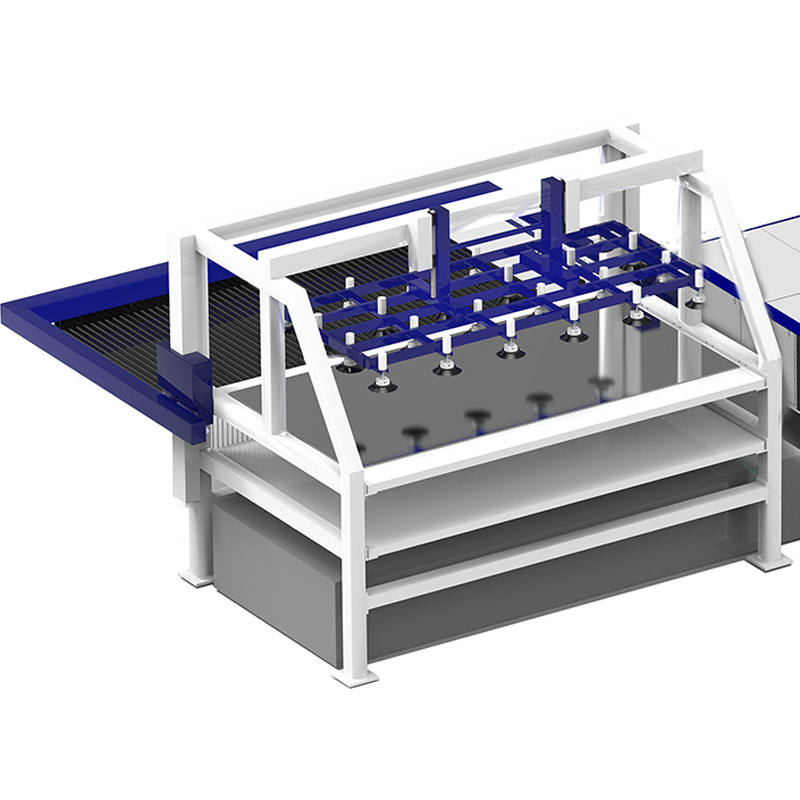

Options