Automobile Parts Manufacturing Industry Introduction

Automobile traction parts usually need to be processed using various machines to meet their complex shapes and high-precision requirements. Common machining equipment includes:

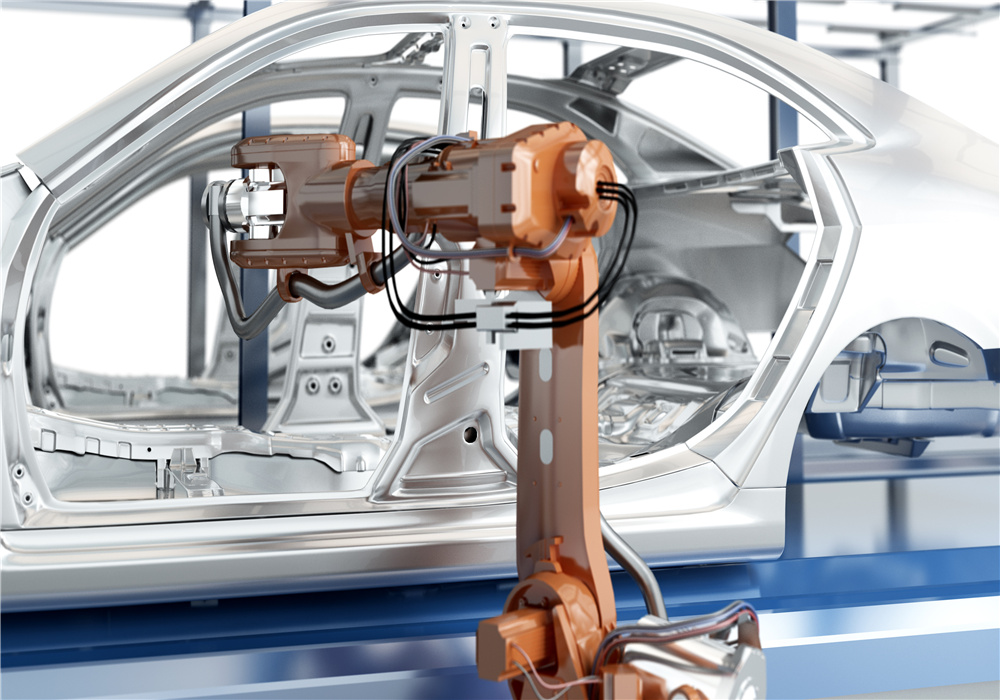

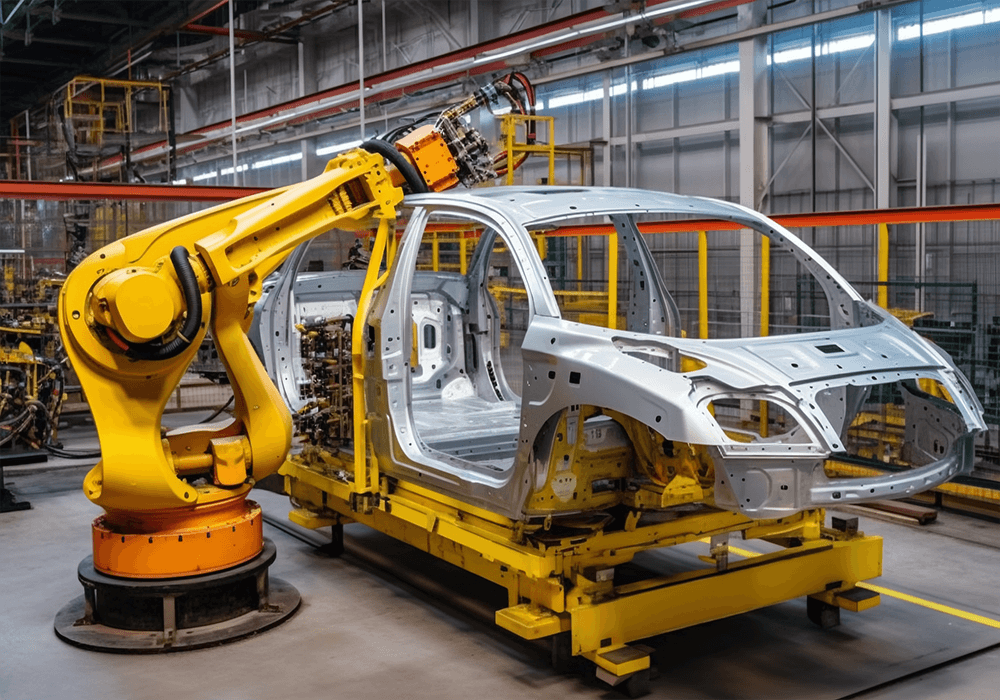

Application Area of Automobile Parts Manufacturing Industry

Why should you take the fiber laser cutter into consideration?

Laser cutting machine can be applied in the processing of automotive parts, such as car interiors, door frames, and various automotive components. Laser cutting machine replaces traditional mechanical blades with an invisible beam of light, offering high precision, rapid cutting, freedom from pattern limitations, automatic nesting to save materials, and smooth cutting edges. In the processing of automotive traction components, the typical materials used are 3mm carbon steel, galvanized sheet, and aluminum sheet under 5mm. Traditional processing methods involve stamping, but currently, most factories are replacing stamping with laser cutting machines, saving the cost of tooling. Laser cutting machines are gradually improving or replacing traditional metal cutting process equipment.

The standard laser cutting machine model 3015/3015H is popular in the automotive parts industry for several reasons:

The 3015 model offers high precision cutting, which is essential for producing intricate and accurate automotive parts.

This model can handle a wide range of materials used in automotive parts, such as carbon steel, galvanized sheet, and aluminum, making it versatile for various applications.

The 3015 model provides fast and efficient cutting, contributing to increased productivity in automotive parts manufacturing.

By replacing traditional cutting methods such as stamping, the 3015 model can reduce tooling costs and material waste, making it a cost-effective solution for automotive part production.

The 3015 model can be integrated into automated production lines, further enhancing its appeal in the automotive parts industry.

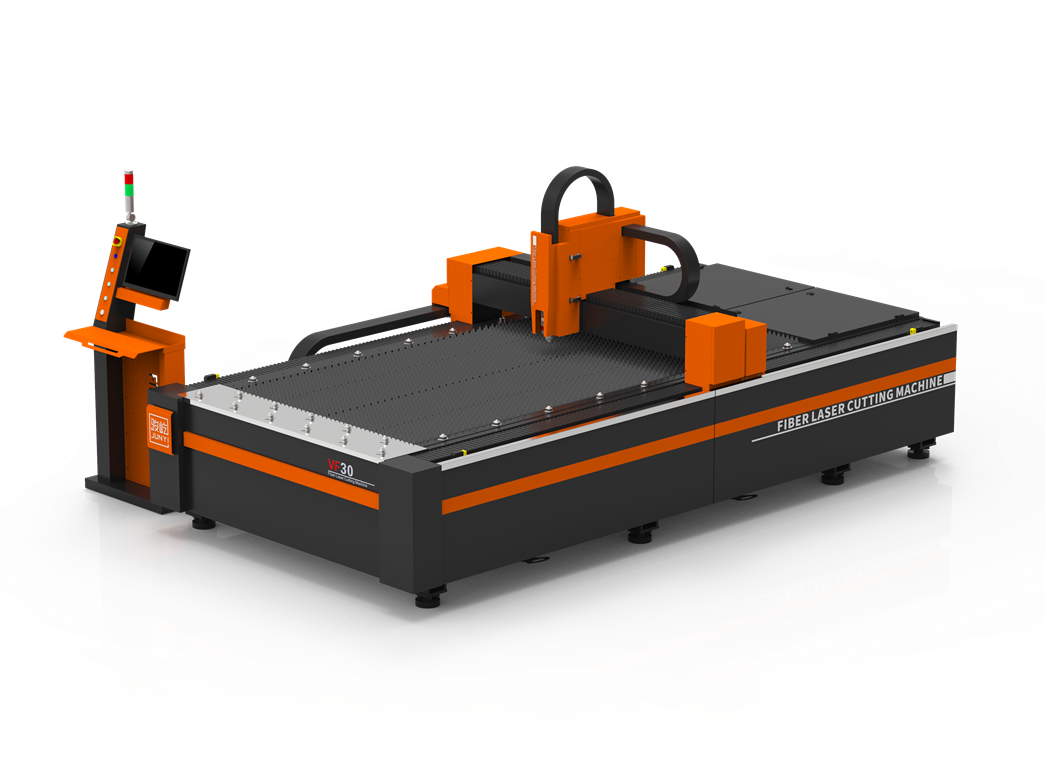

VF3015 standard fiber laser cutter

The 3015 model’s combination of precision, versatility, efficiency, cost-effectiveness, and automation compatibility makes it a popular choice for manufacturing automotive parts.

Read more

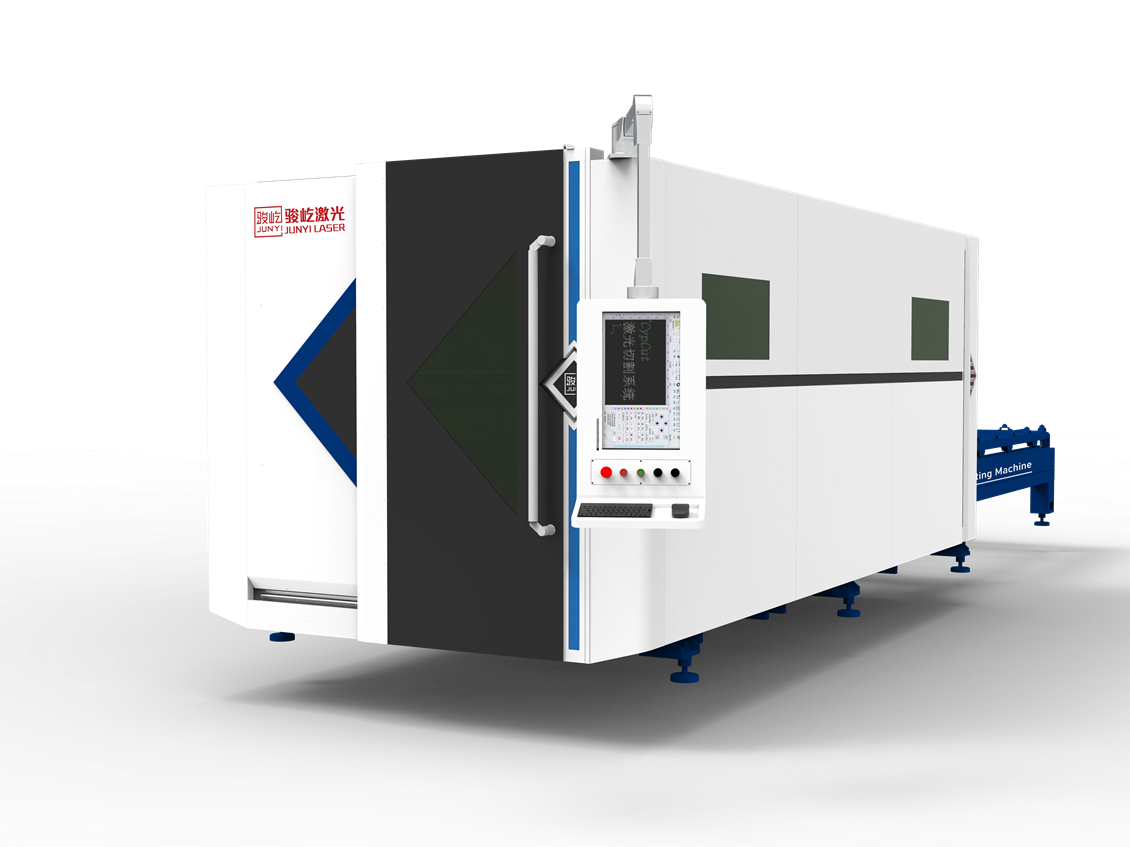

VF3015H dual platform fiber laser cutter

The 3015H model is a double-platform design with a surrounding structure. The rear side of the equipment can be cut up and down at the same time. It is suitable for...

Read more|

Model |

VF3015 |

VF3015H |

|

Working area |

5*10 feet(3000*1500mm) |

5*10 feet *2(3000*1500mm*2) |

|

Size |

4500*2230*2100mm |

8800*2300*2257mm |

|

Weight |

2500KG |

5000KG |

|

Cabinet installation method |

1 set of machine:20GP*1 2 sets of machine:40HQ*1 3 sets of machine:40HQ*1( with 1 iron frame) 4 sets of machine:40HQ*1( with 2 iron frames) |

1 set of machine:40HQ*1 1 set of 3015H and 1 set of 3015:40HQ*1 |

Samples of Automobile parts

Main Advantages of 3015H Fiber Laser Cutting Machine

The overall size of Junyi laser equipment is: 8800*2300*2257mm. It is specially designed for export and can be directly installed in cabinets without removing the large external enclosure. After the equipment arrives at the customer's site, it can be directly connected to the ground, saving freight and installation time.

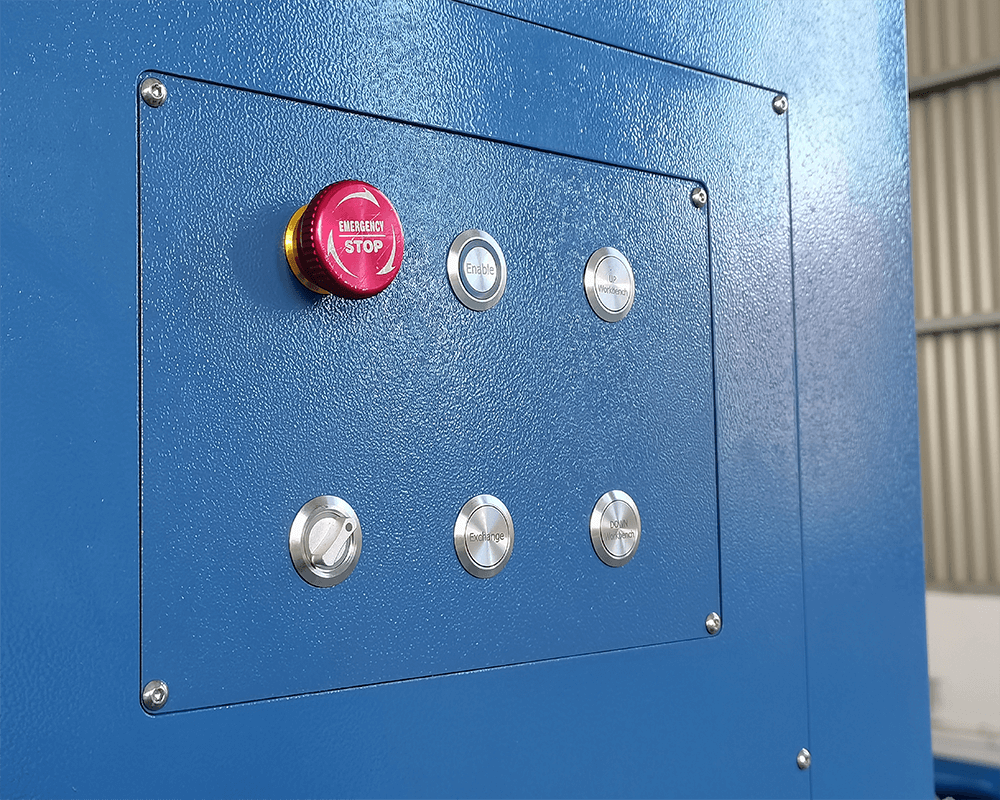

The middle part of the equipment is designed with a platform exchange button and an emergency stop switch. It adopts a lean management solution. Workers can operate directly in the middle of the equipment when changing plates, loading and unloading materials, improving work efficiency.

Cost Analysis

For example,VF3015-2000W laser cutter:

| Items | Cutting stainless steel (1mm) | Cutting carbon steel (5mm) |

| Electricity fee | RMB 13/h | RMB 13/h |

| Expenses of cutting auxiliary gas | RMB 10/h (AIR) | RMB 14/h (O2) |

| Expenses of protective lens, cutting nozzle | Depend on the actual situation | Depend on the actual situation RMB 5/h |

| Totally | RMB 23/h | RMB 27/h |

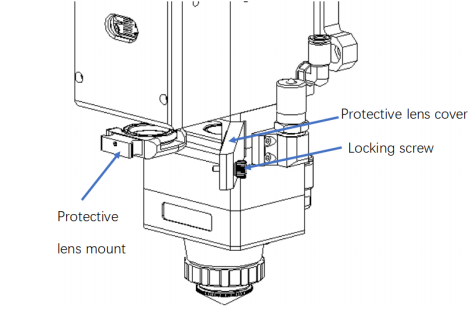

Maintenance of Protective Lens

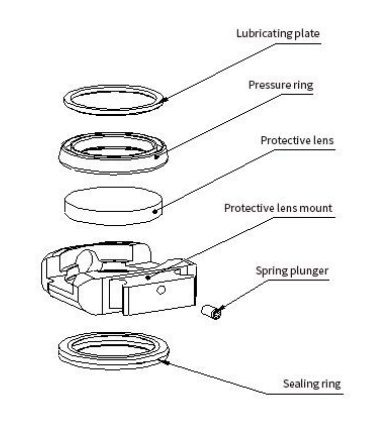

Removal and Installation of Lens

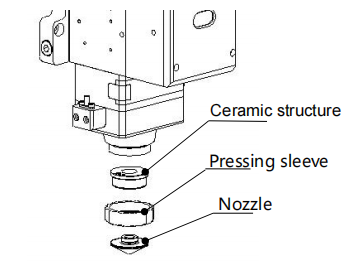

Replace Nozzle Connection Assembly

Replace Ceramic Structure