Electrical Cabinets Industry Introduction

Application of Fiber Laser Equipment

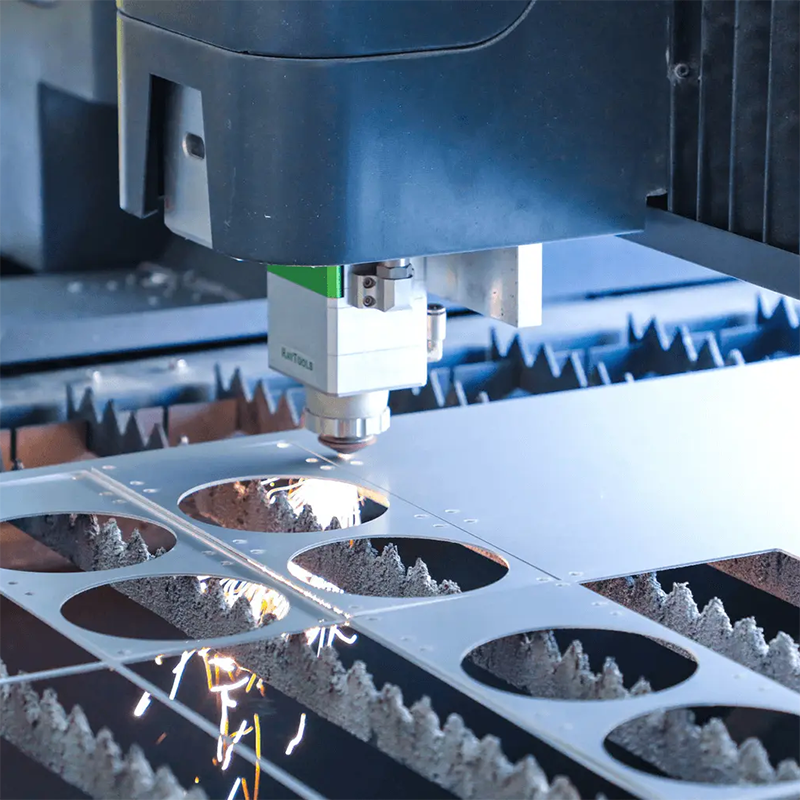

Ⅰ. Laser Cutting

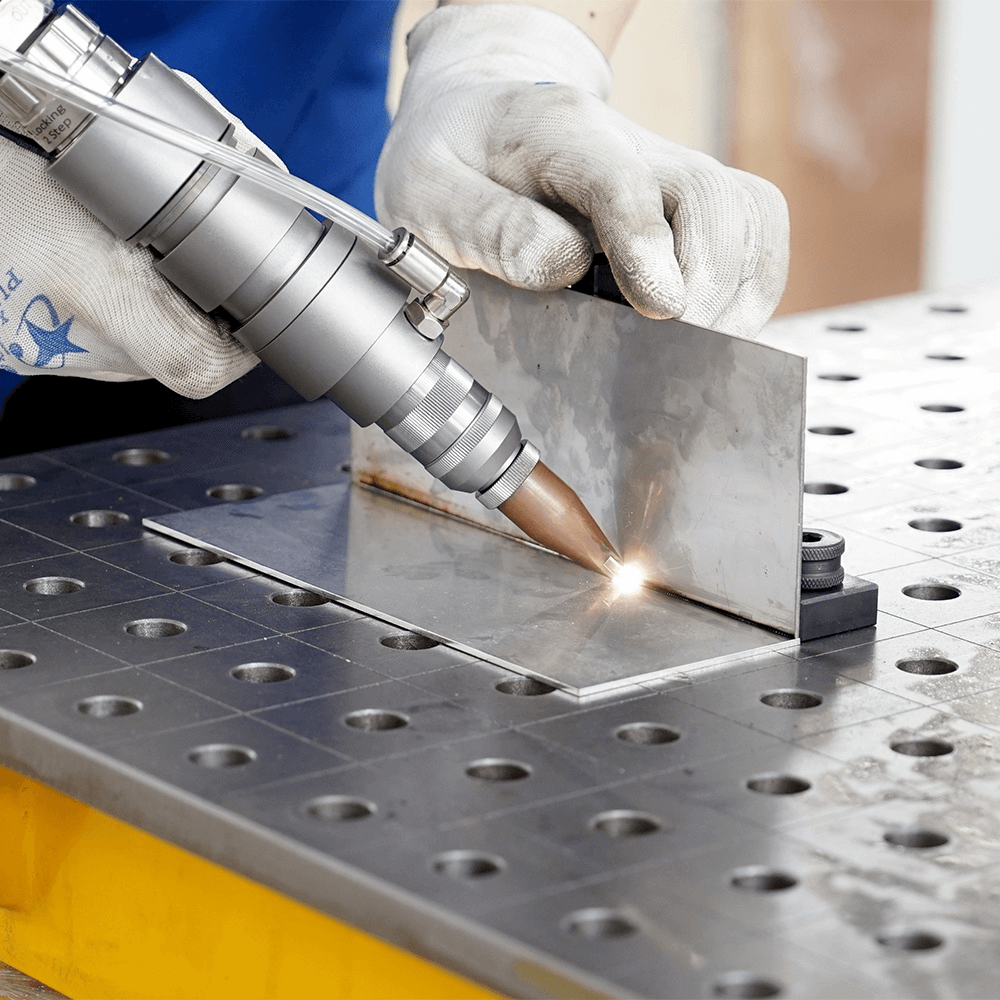

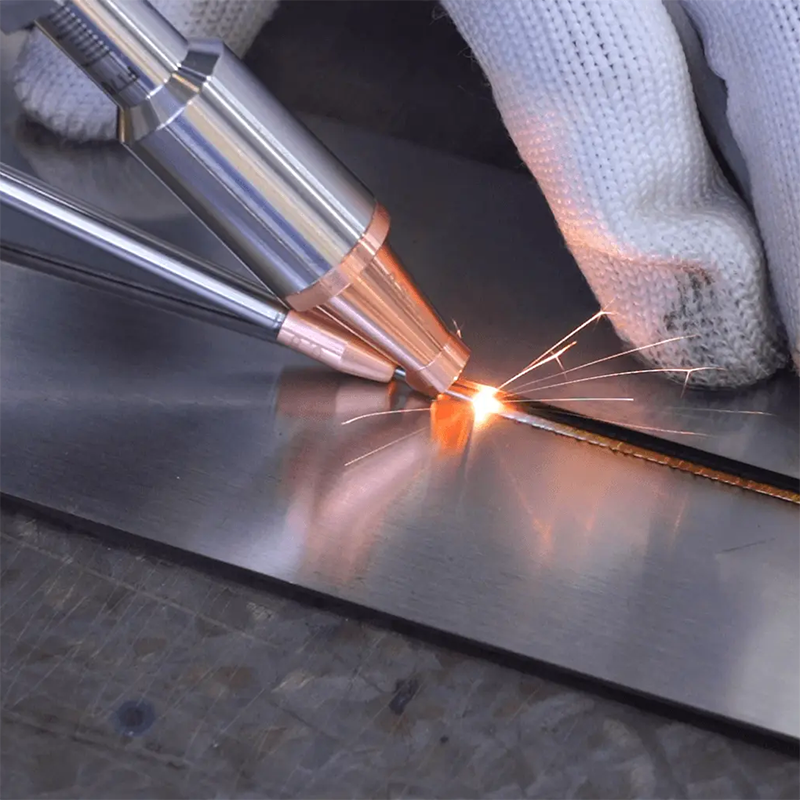

Ⅱ. Laser Welding

● Flexibility: The laser handheld welding machine has flexible operability and can more easily handle complex welding locations and angles when welding electrical cabinets.

● Portability: Compared with traditional welding equipment, laser handheld welding machines are lighter and easier to carry out welding operations inside electrical cabinets or in small spaces.

● High precision: Laser welding technology can achieve high-precision welding and ensure the accuracy and quality of the welded parts.

● Low heat-affected zone: The heat-affected zone during the laser welding process is very small, which can reduce deformation and thermal impact, and is suitable for welding that has strict structural requirements for electrical cabinets.

● High degree of automation: The laser handheld welding machine can realize semi-automatic or fully automatic welding, improving production efficiency and reducing labor costs.

Benefits from laser cutting and welding machine

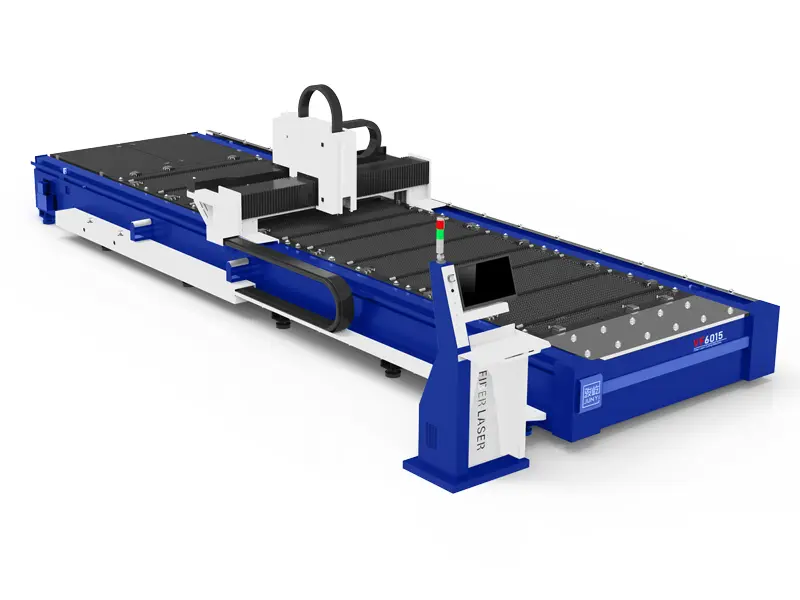

Upgraded 6 Meters Fiber Laser...

| Model | VF6015 |

|---|---|

| Laser power | 1500-6000W |

| Size | 8196*2230*2394mm |

| Weight | 3600KG |

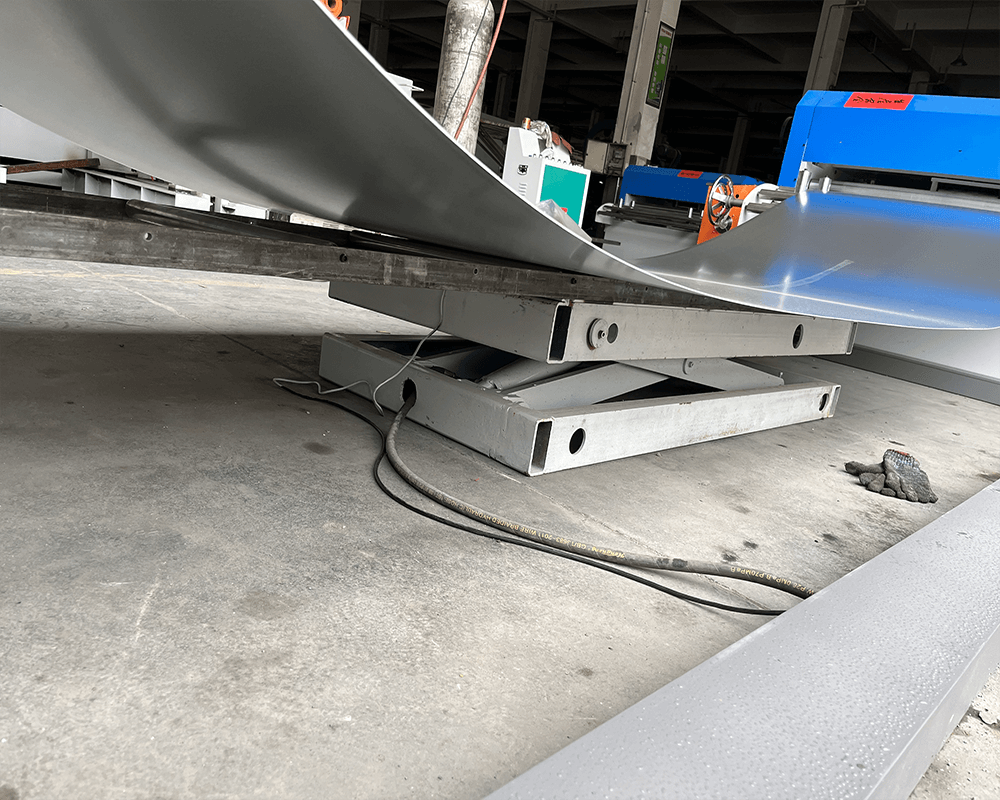

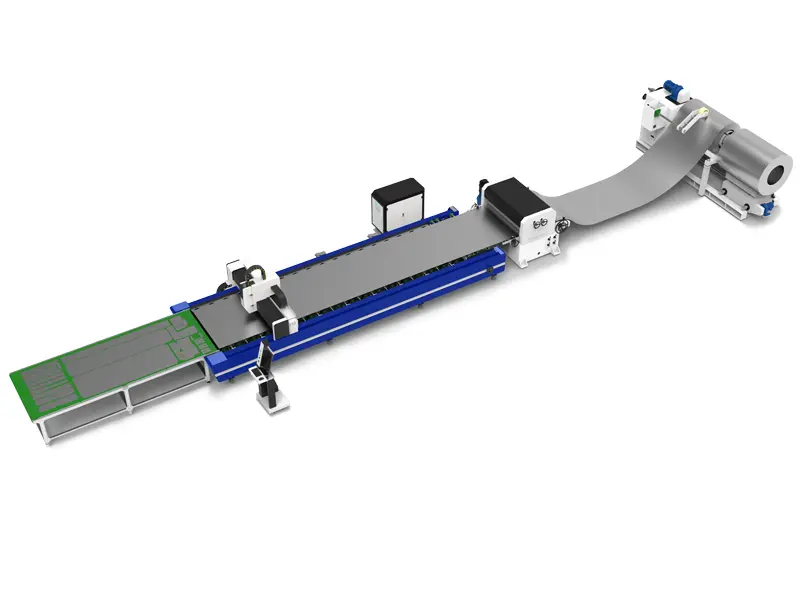

Automatic Feeding System...

| Model | VF6015C |

|---|---|

| Laser power | 1500-6000W |

| Size | 35600*7500*2394mm |

| Weight | 3600KG(machine) |

Four-In-One Hand-Held Laser...

| Model | HW-1500W |

|---|---|

| Laser power | 1500-3000W |

| Size | 958*496*794mm |

| Weight | 184KG |

Highlights of VF6015C Steel Coil Laser Cutter

The standard laser cutting machine model 3015/3015H is popular in the automotive parts industry for several reasons:

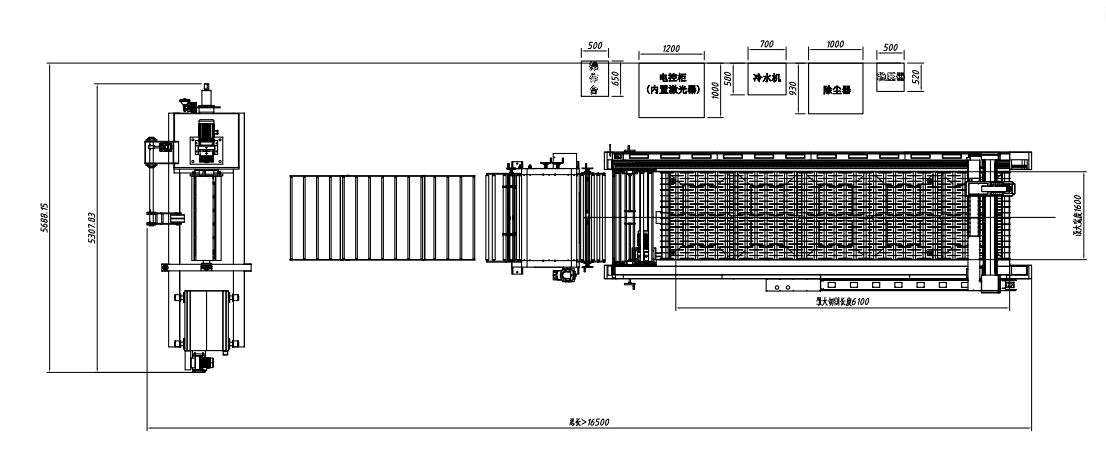

Site and Environmental Requirements

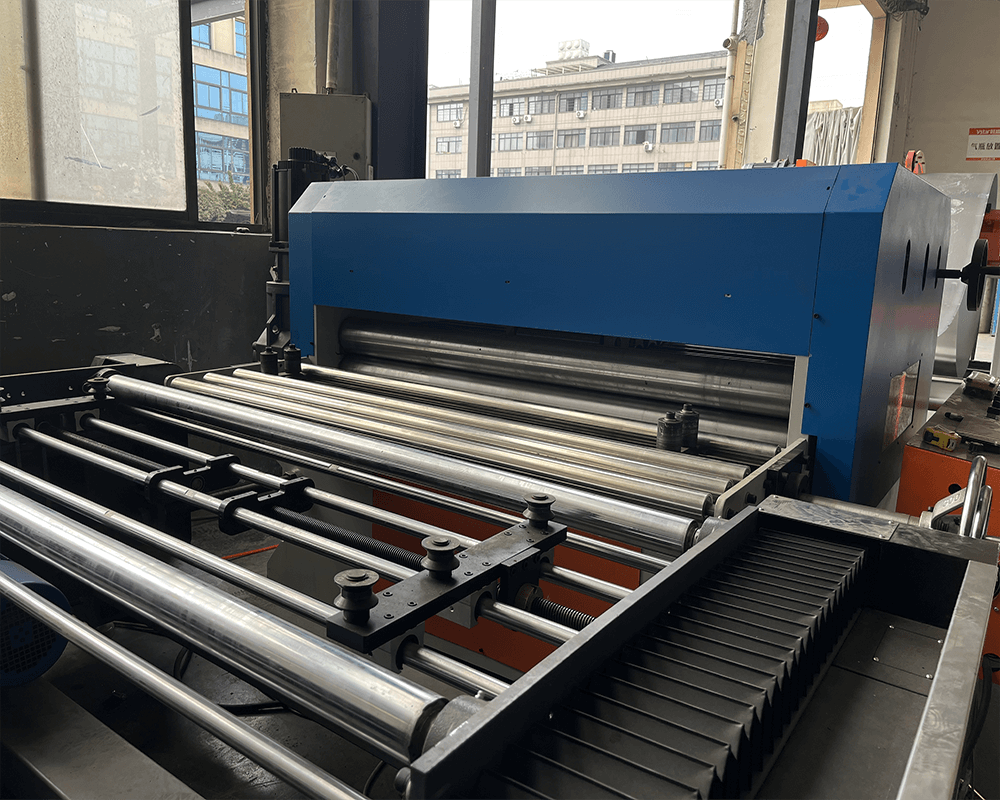

Structure of uncoiling fiber laser cutting machine

| Material seat shape | The load-bearing surface is a V-shaped structure |

|---|---|

| Trolley walking drive mode | Cycloid motor |

| Trolley lifting drive method | Hydraulic cylinder |

| The way the trolley prevents walking offside | Hard limit |

| Maximum load | 15ton |

| Control method | Manual button control |

| Alignment method | Visual alignment, scale attached as reference |

| Loading roll width | 200-1500mm |

| Load capacity | 12 ton |

| Expansion method | Hydraulic wedge structure |

| Expansion range | 480-520 |

| Spindle drive method | AC variable frequency motor |

| Spindle transmission mode | Double row large spacing chain drive |

| Braking method | Pneumatic butterfly brake |

| Unwinding flow | Lower unwinding method |

| Press arm drive | Pneumatic drive |

| Material arc control | Photoelectric switch control |

| Power mode | Servo motor |

| Correction amount adjustment method | Servo CNC control |

| Correction amount display method | Digital display |

| Correction roller | 11 pieces, two groups of 5 upper and 6 lower, roller diameter 84mm |

| Pre-pressure roller | 3 pieces |

| Length roller | 2 pieces, 1 upper and 1 lower, roller diameter 120mm |

| Servo method for roller | Side gear drive |

| Training wheels | 2 columns |

| Auxiliary wheel bearing | Aligning bearings |

| Roller material | High-quality bearing steel, after hardening treatment, the hardness can reach HRC60±2 |

| Feeding repeatability | 0-1000mm ±0.15,>1000mm ±0.25 |

| Maximum feeding speed | 16m/min |