01

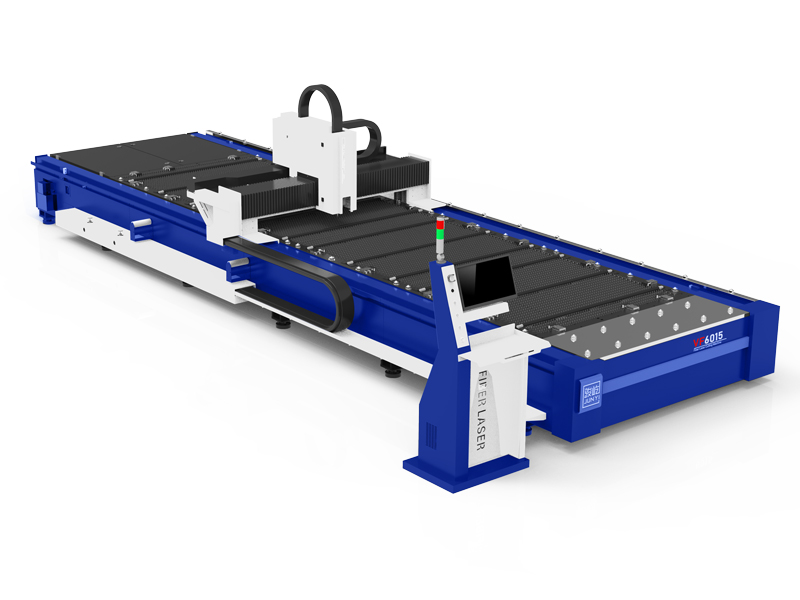

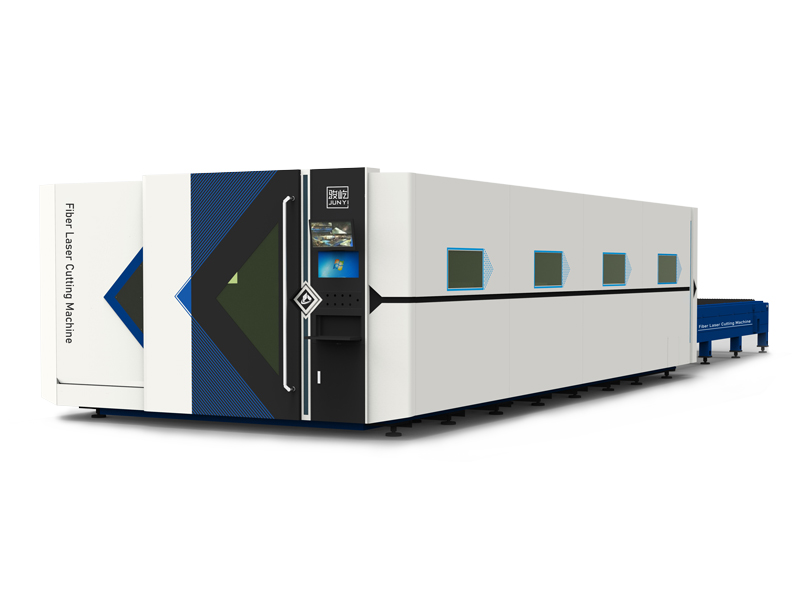

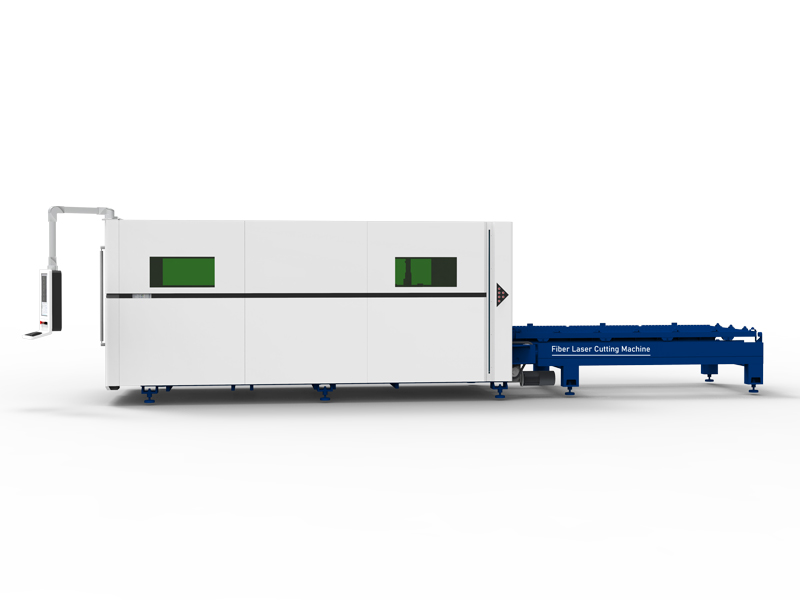

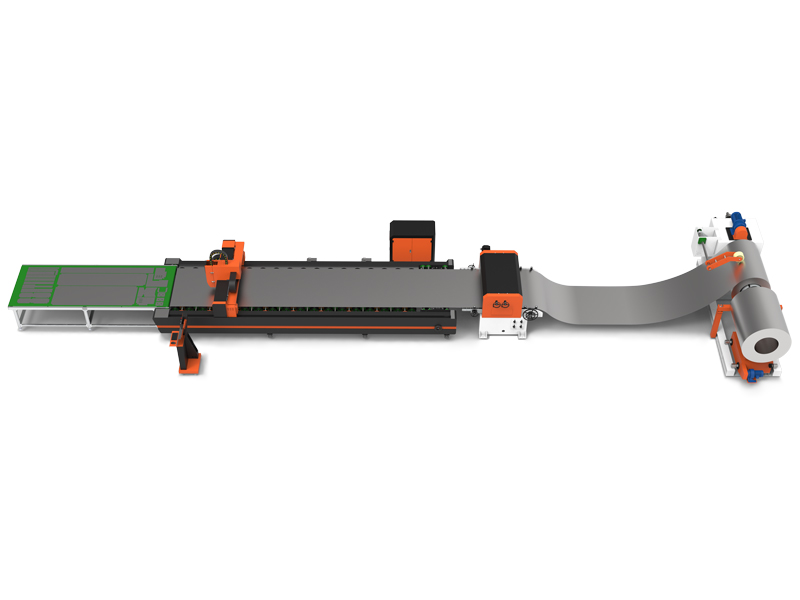

Automatic Feeding System VF6015 Rolling Cutting Machine

Video

Machining Process

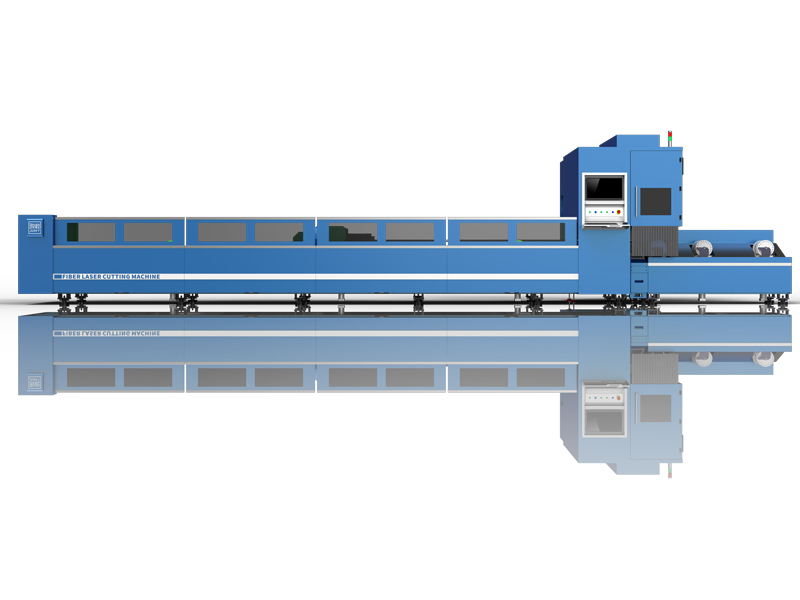

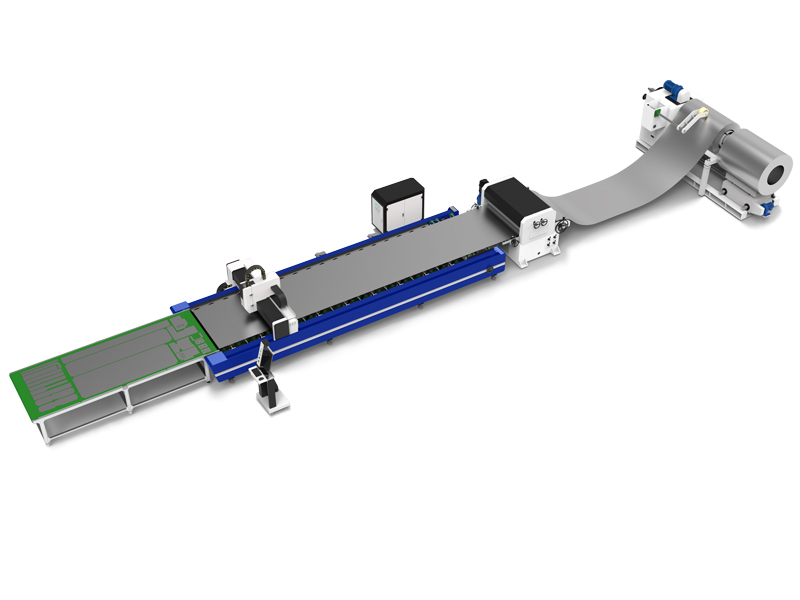

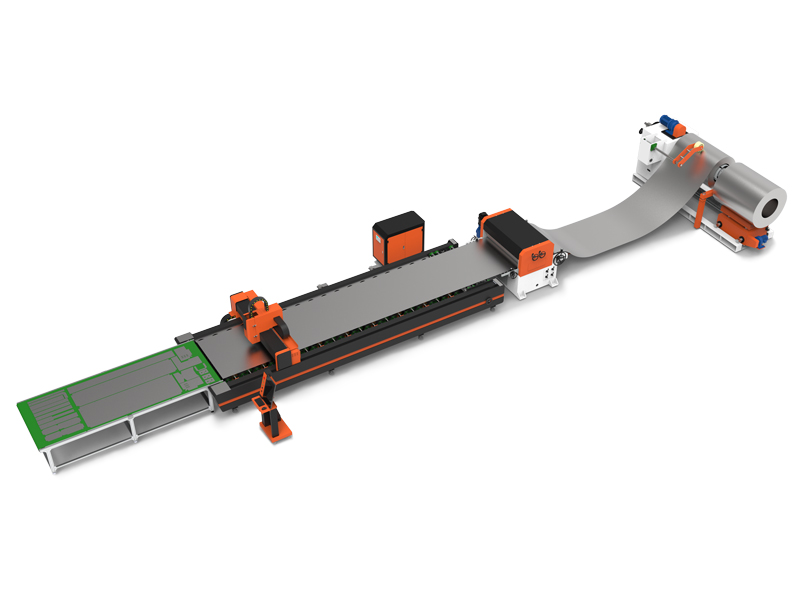

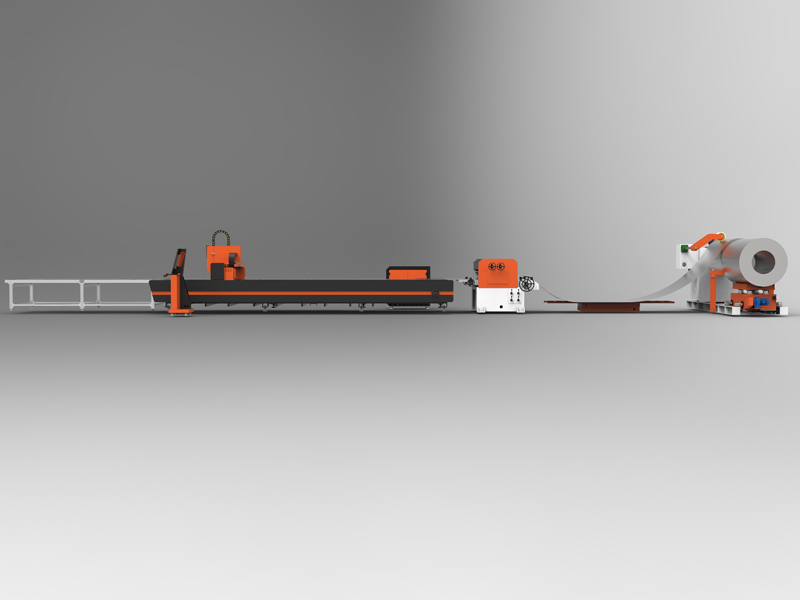

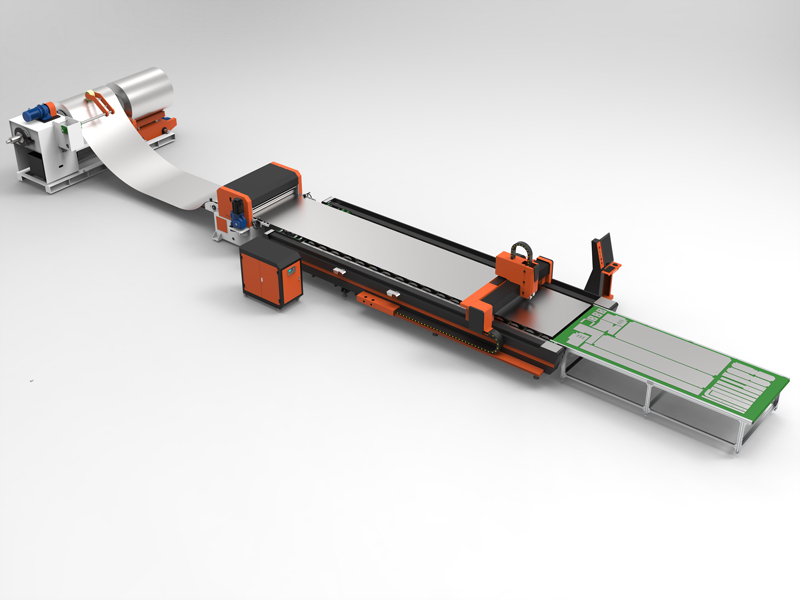

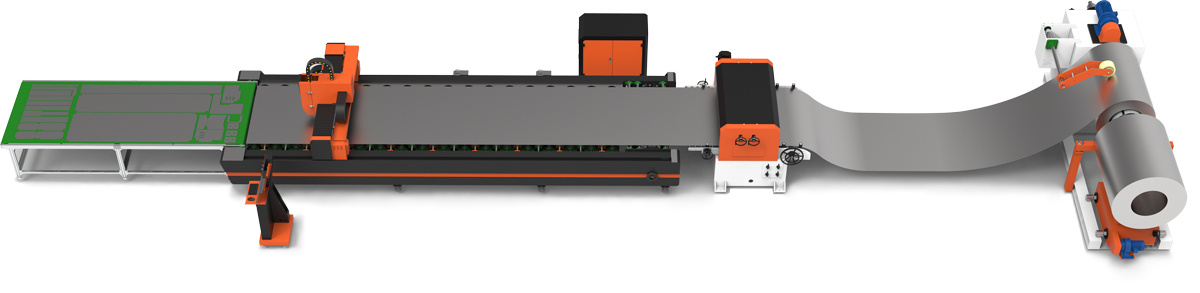

Uncoiling and Blanking Cutting Production Line, an innovative solution that revolutionizes the coil cutting process. This integrated system provides seamless operations for coil unwinding, correction, follow-up cutting, and blanking, all in one efficient package.

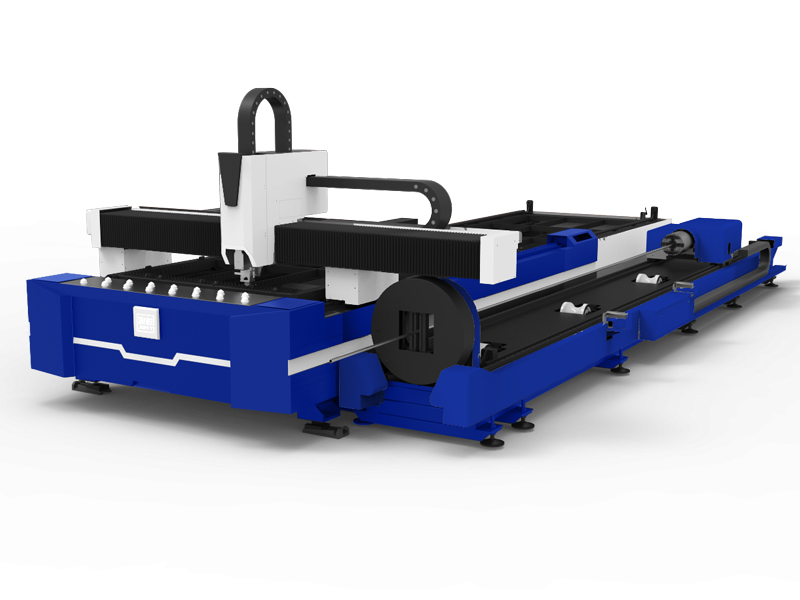

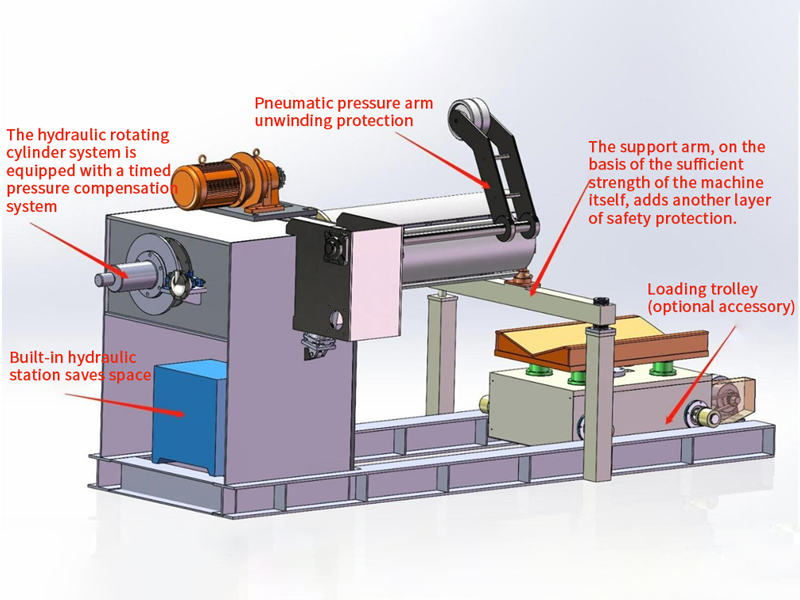

The complete system consists of several components that work together to optimize the production process. It starts with the coil feeding trolley, which allows for easy transportation of the coils. The single-arm decoiler ensures smooth and controlled unwinding of the coil, while the hydraulic auxiliary support enhances stability during operation. A feeding device seamlessly delivers the coil to the leveling machine, guaranteeing precise and even material alignment.

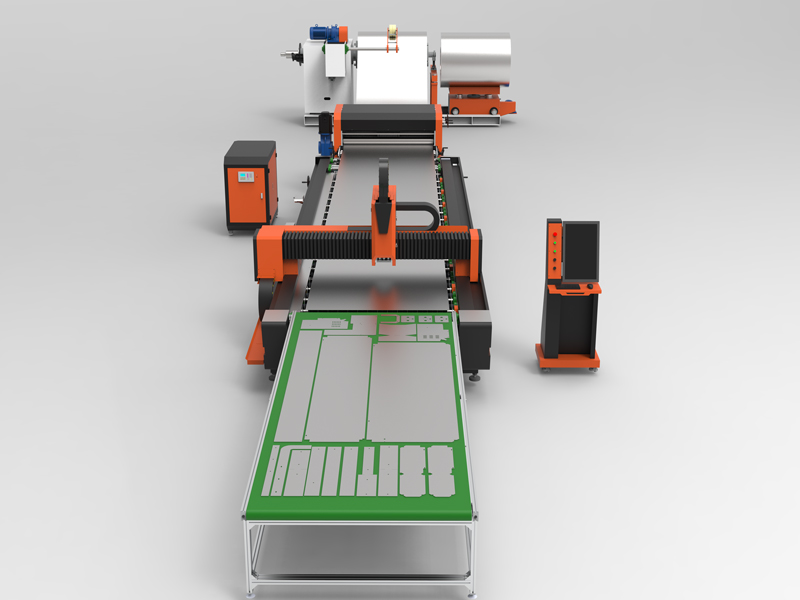

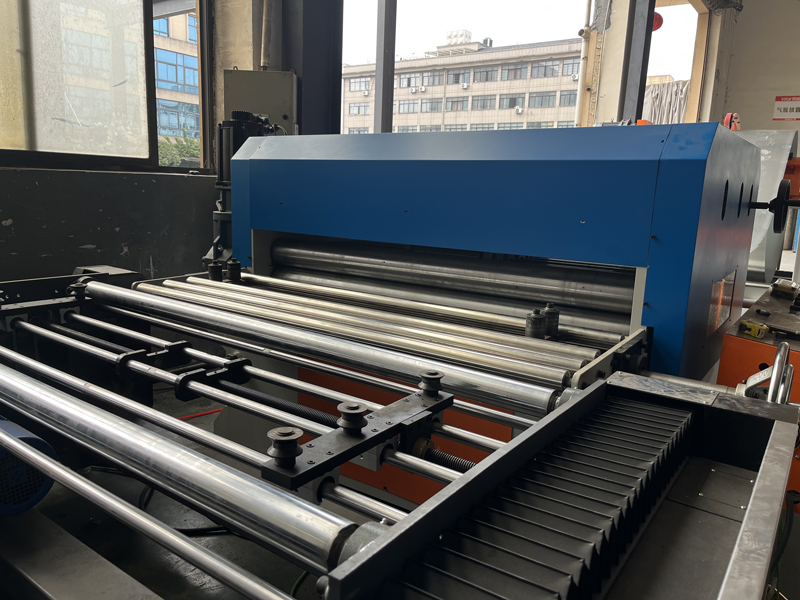

With the guide device in place, the rolling cutting platform ensures accurate and consistent cutting. But what sets this production line apart is the inclusion of a laser cutting system. This advanced technology simplifies the cutting process, eliminating the need for manual shearing and reducing overall processing time.

Efficiency is further enhanced with the material receiving platform, which collects the cut materials, ready for further processing or packaging. The hydraulic and pneumatic system, along with the electrical control system, ensures smooth and reliable operation throughout.

Gone are the days of cumbersome coil flattening and manual cutting. With the Uncoiling and Blanking Cutting Production Line, material utilization is improved, reducing waste and ultimately saving costs. The labor-intensive tasks are streamlined, considerably reducing labor costs and increasing productivity.

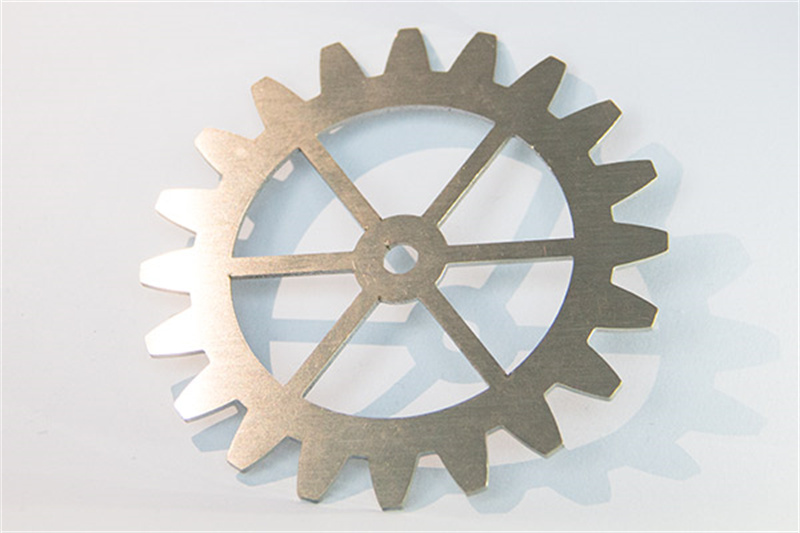

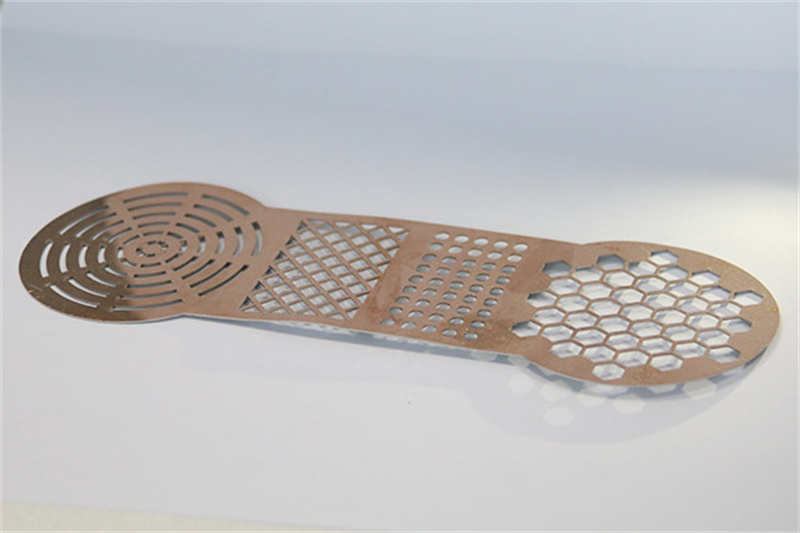

The system is particularly suitable for large-volume processing and diverse graphic cutting requirements. It not only saves additional costs associated with punch molds but also significantly enhances production efficiency. The ability to integrate the entire cutting process into one seamless operation makes this production line a game-changer for industries requiring precision cutting and blanking.

Invest in the Uncoiling and Blanking Cutting Production Line today and experience the ultimate cutting-edge solution for your coil processing needs. Streamline your production, reduce costs, and elevate your efficiency to new heights with this state-of-the-art system.

SPECIFICATIONS

Processing width(L*D) |

6000*1500 (mm) |

|

Maximum acceleration |

0.8g |

|

X axis |

Rapid moving speed |

80m/min |

Effective stroke |

6000mm |

|

Positioning accuracy |

±0.05mm |

|

Repeat accuracy |

±0.05mm |

|

Y axis |

Rapid moving speed |

80m/min |

Effective stroke |

1500mm |

|

Positioning accuracy |

±0.05mm |

|

Repeat accuracy |

±0.05mm |

|

Power supply |

AC380V±5% 50/60Hz 3Phase |

|

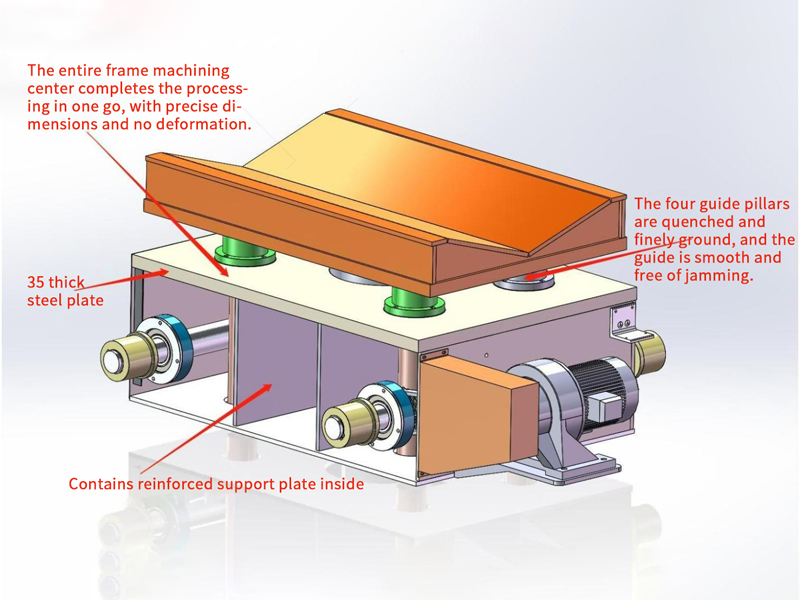

To safely and smoothlymove the material onto the expanding and contracting structure of the unwinder, it is necessary to have a support mechanism to elevate the material during unwinding. This will facilitate the smooth entry of the strip into the leveling machine. Additionally, a trolley equipped with an anti-tilting mechanism can be used to transport narrower material coils.

It is very important to fix the inner diameter of the roll in the expansion and contraction area. A hydraulic rotary cylinder with a diameter of 150*100 can be used to realize intermittent rotation and discharge of materials. At the same time, a timed pressure compensation system can also be installed to ensure that the tightness of the material roll will not be affected by pressure relief during long-term use. In addition, adding a support arm to the front end of the machine can further increase safety and provide additional support for the machine.

We have added the most advanced servo automatic adjustment opening and closing mode to the feeding mechanism to automatically match the thickness or type of different materials. This greatly reduces the time and material costs previously spent on the adjustment process, making the operation easier. In addition, in response to the problem that conventional materials may have their rolls tilted up, we have also added a pre-pressure device to the equipment, which solves this problem in advance and eliminates the need for users to reinstall the materials. These improvements not only increase efficiency, but also simplify the operation process, making it easy for even novice operators to use the equipment without worrying about finding suitable skilled workers.

The design of the hydraulic lifting bridge does provide convenience and safety to the operator. The hydraulic system allows the operator to easily raise the ferry bridge to the desired height without having to touch the material with hands. This greatly reduces the risk of worker injury and increases work efficiency. When the material to be processed enters the screen opening machine, the bridge will automatically lower to the lowest point and act as a material support device. This design can effectively reduce friction on the material surface and protect the integrity of the material surface. At the same time, the lowering of the ferry bridge can also provide a better working angle, allowing the operator to operate more easily.

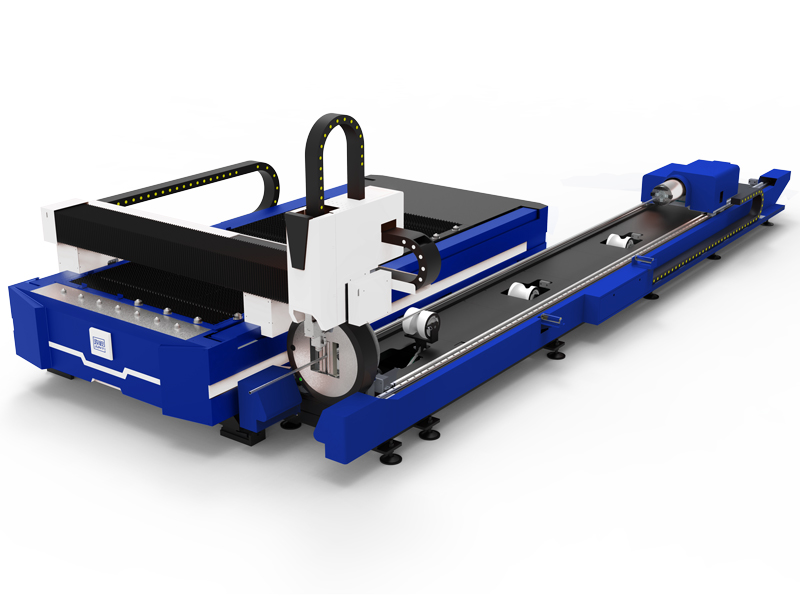

The mechanical structure of the unloading device includes the following main components:

Aluminum profile frame: Using aluminum profiles as the main structure, it has the characteristics of lightweight, high strength and corrosion resistance, and can provide stable support and frame structure.

Enhanced conveyor belt: Used for the transmission of workpieces. The enhanced design ensures smooth movement of workpieces during transmission and improves production efficiency and quality.

Adjustable guide mechanism: By adjusting the guide mechanism, you can ensure that the workpiece moves accurately along the set direction and width to avoid offset and misalignment.

Simple blanking rack: In order to facilitate the palletizing and forklift transportation of workpieces, a simple blanking rack is designed, which can easily place and remove workpieces.

Speed control: Use a frequency converter to control the speed of the conveyor belt, which can be adjusted as needed. The maximum speed can reach 10 meters/minute to adapt to different processing needs.

Conveying length: The standard conveying length is 4000mm, but different lengths can also be customized as needed to meet the processing requirements of workpieces of different sizes.

0102

Leave Your Message

0102