01

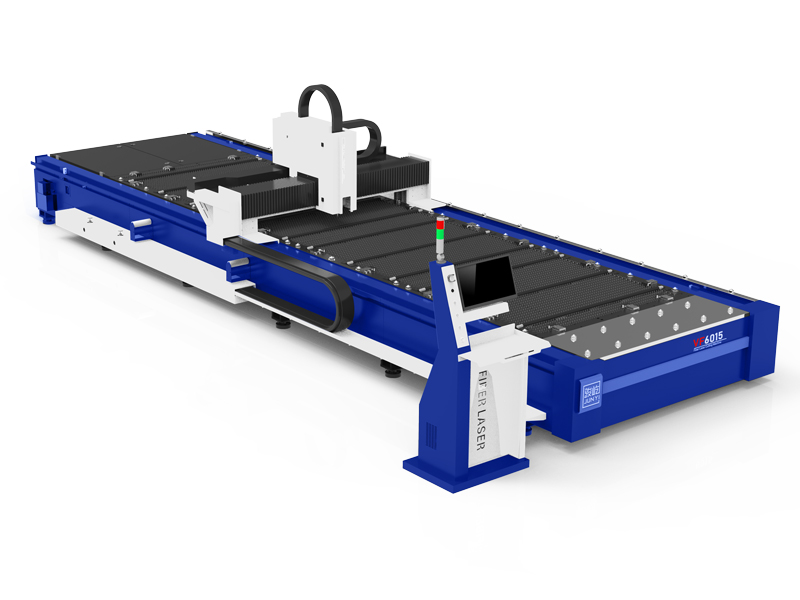

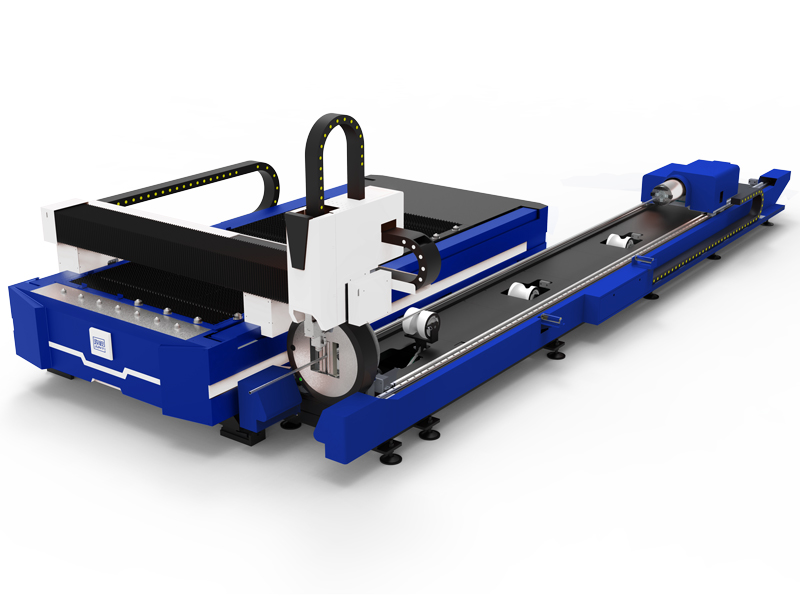

Precision Laser Cutter With Compact Design

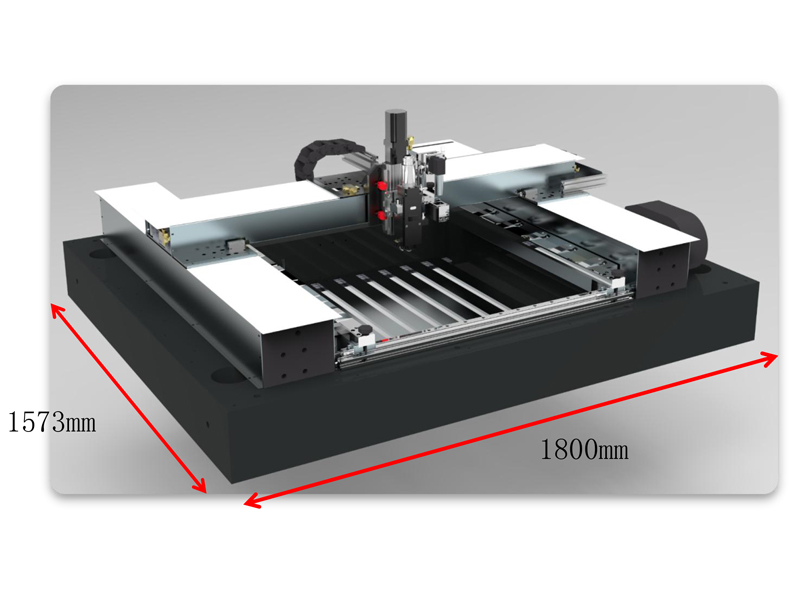

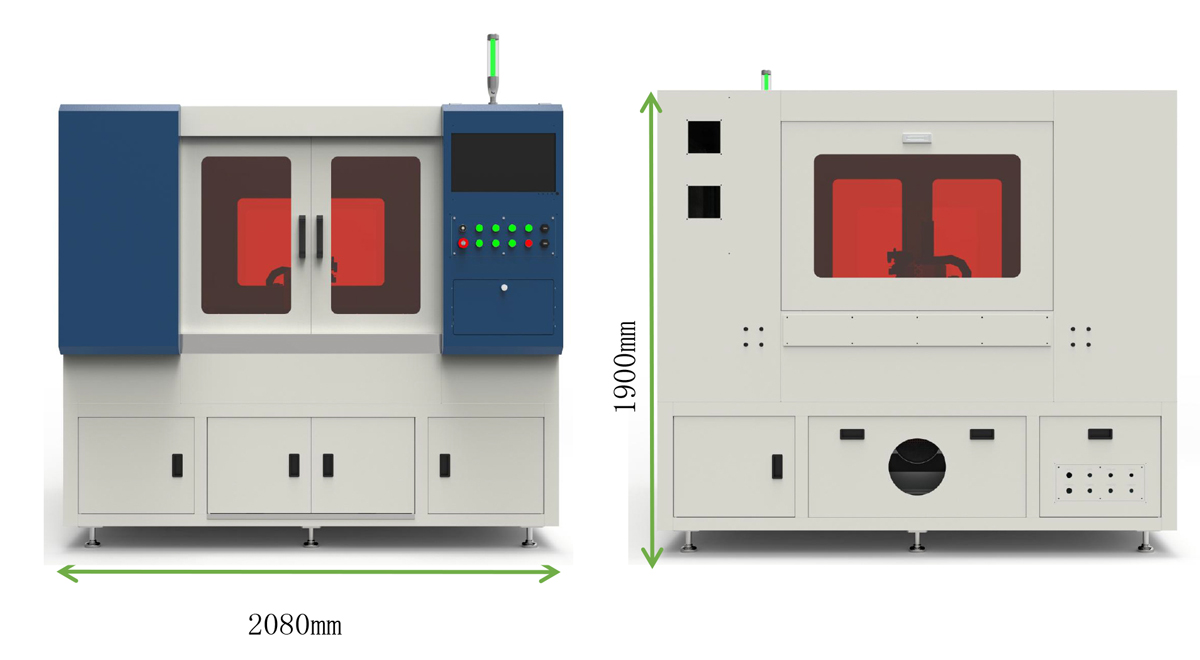

SPECIFICATIONS

Processing width |

800*800 (mm) |

|

Maximum acceleration |

1.0g |

|

x-axis |

Rapid moving speed |

60m/min |

Effective stroke |

800mm |

|

Positioning accuracy |

±0.02mm |

|

Repeat accuracy |

±0.005mm |

|

Y-axis |

Rapid moving speed |

60m/min |

Effective stroke |

800mm |

|

Positioning accuracy |

±0.02mm |

|

Repeat accuracy |

±0.005mm |

|

Z-axis travel |

100mm |

|

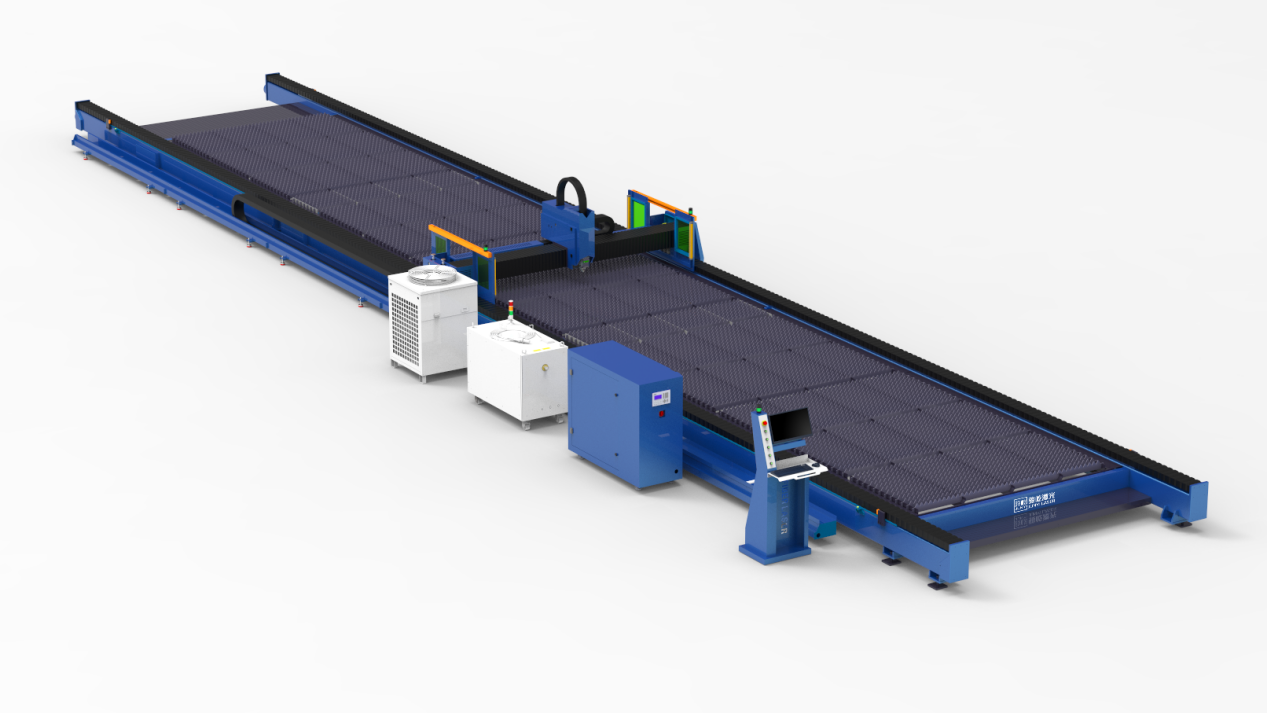

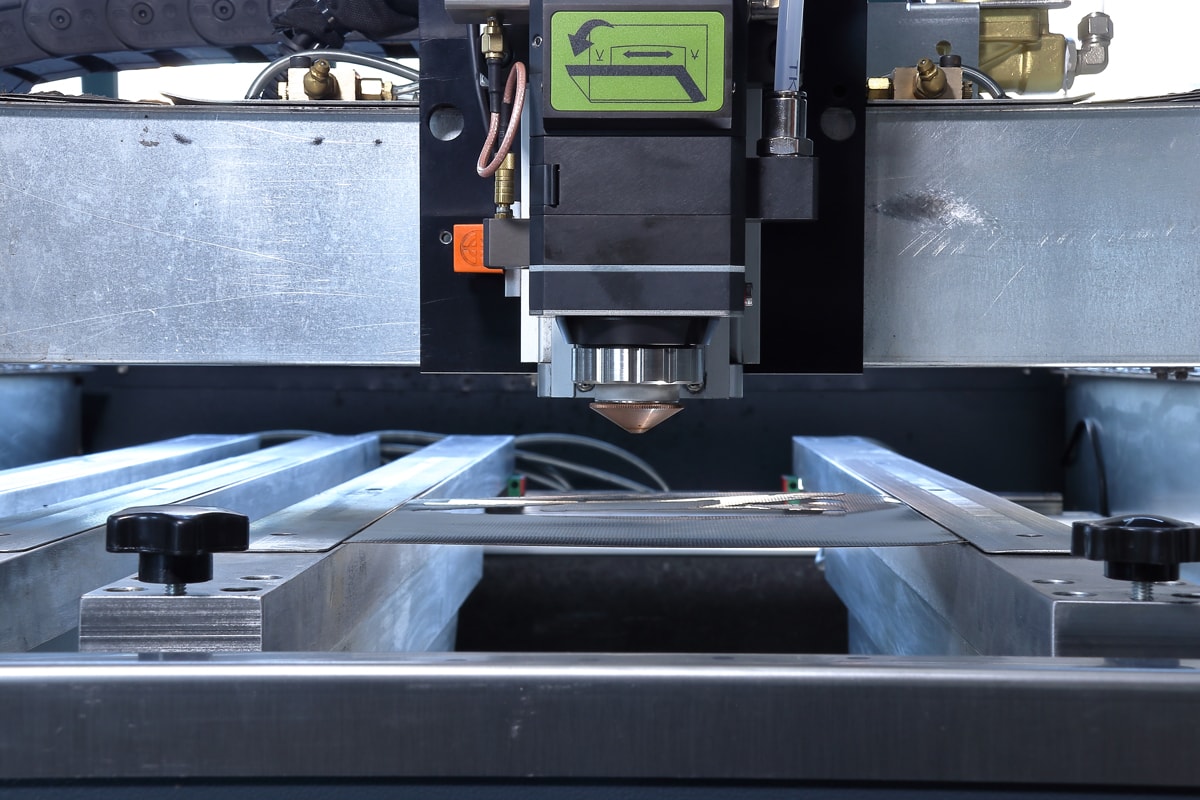

Choosing marble as the beam for laser cutting equipment has the following advantages:

High rigidity: Marble has high hardness and density, giving it excellent rigidity when carrying lasers and worktables. This can provide a stable cutting environment and maintain high cutting accuracy.

Shock resistance: Marble has good shock resistance, which can reduce the impact of external vibration on the equipment, thereby improving cutting accuracy and stability. Wear resistance: Marble has high surface hardness and can well resist wear and thermal deformation during cutting, extending the service life of the beam.

Not magnetized: Compared with metal materials, marble is not magnetized, which can prevent the beam from being disturbed by external magnetic fields during the laser cutting process.

Thermal stability: Marble has a low thermal expansion coefficient, which can effectively reduce cutting errors caused by thermal deformation and maintain high cutting accuracy.

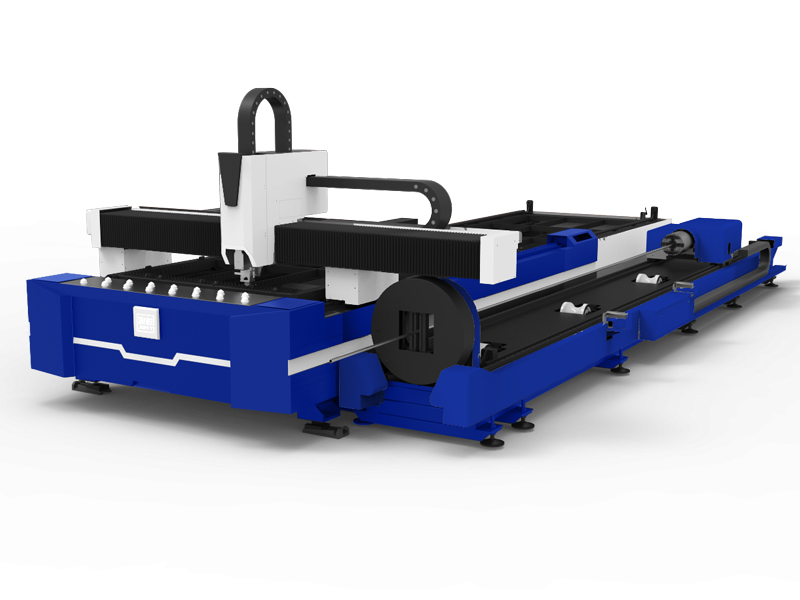

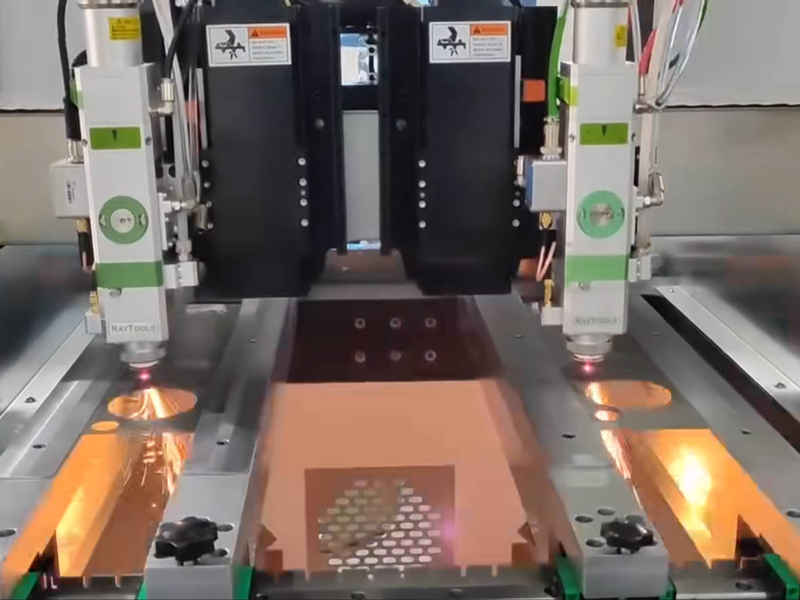

Laser cutting equipment equipped with two cutting heads can bring the following advantages:

Improve production efficiency: Double-head cutting equipment can perform two cutting tasks at the same time. Compared with single-head equipment, it can effectively reduce cutting time and improve production efficiency. Especially suitable for production scenarios that require large amounts of cutting.

Increased cutting capacity: Double-head cutting equipment can be equipped with different power laser sources for different cutting heads, providing a wider range of cutting capabilities. It can meet the cutting needs of different materials and thicknesses, improving the flexibility and applicability of the equipment.

Enhanced cutting accuracy: Double-head cutting equipment can cut materials simultaneously by performing two cutting processes at the same time, thereby improving cutting accuracy and consistency. Especially for large materials or batch cutting, double-head equipment can better maintain cutting quality and accuracy.

Improve equipment utilization: Double-head cutting equipment can perform two cutting tasks at the same time, reducing idle time and improving equipment utilization. In busy production environments, customer needs can be better met and production capacity increased.

Increase the stability and reliability of the equipment: Double-head cutting equipment usually has more powerful power supply and control system support, which can run better and provide higher reliability. The double-head cutting equipment has a redundant backup function, that is, when one head fails, the other head can continue to work without affecting the entire cutting process.

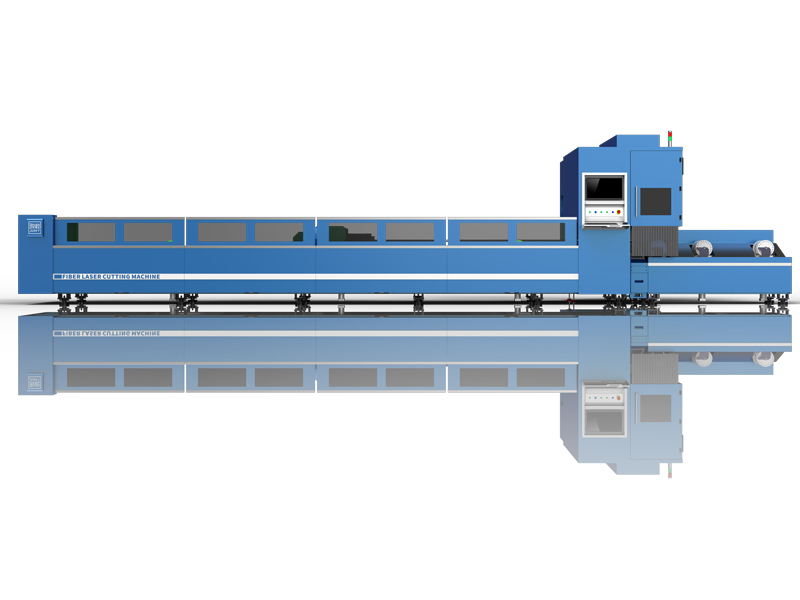

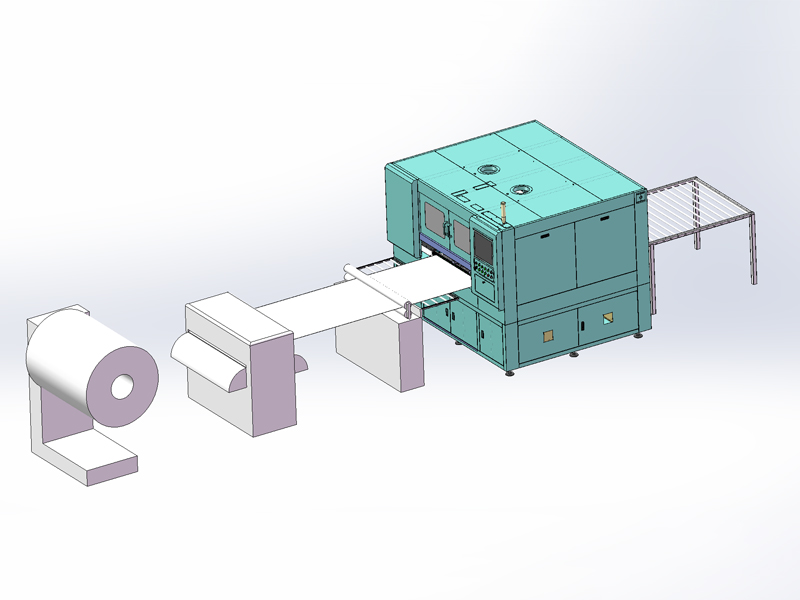

Precision cutting equipment equipped with automated loading devices has the following advantages:

Improve production efficiency: The automated loading device can quickly and accurately feed the material to be cut into the equipment without manual operation, thus saving loading time and labor costs, and enabling continuous and stable production, improving production efficiency.

Improve cutting accuracy: Through precise positioning and control, the automated loading device can accurately place the material to be cut at the designated location of the equipment, ensuring the accuracy and consistency of the cutting position and improving cutting accuracy.

Reduce personnel labor intensity: The automated loading device can replace manual labor in loading materials into the equipment, reducing personnel labor intensity and reducing the impact of human factors on cutting quality.

Reduce material waste: The automated feeding device can accurately calculate and control the location and quantity of materials according to the set cutting plan, minimizing material waste and improving material utilization.

Increased safety: The automated loading device reduces the risk of personnel contacting the equipment and improves work safety by reducing manual operations. At the same time, automation devices are usually equipped with safety protection devices to ensure the safety of operators.

contrast

Introducing our Precision Cutting Equipment

We are thrilled to introduce our latest innovation in laser cutting technology - Precision Cutting Equipment. Designed to surpass ordinary laser cutting equipment, our Precision Cutting Equipment offers a multitude of advantages that will revolutionize your cutting tasks.

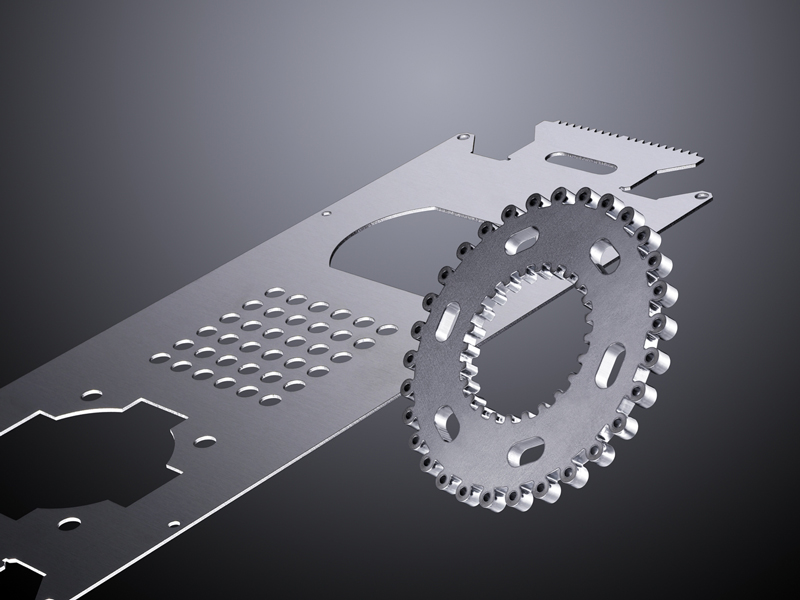

One of the standout features of our Precision Cutting Equipment is its higher cutting accuracy. By incorporating state-of-the-art optical systems and control technologies, we have achieved a level of precision that is unparalleled in the industry. This means that even the most delicate and complex cutting tasks can be accomplished with ease, resulting in cutting edges that are more precise and cutting widths that are narrower.

In addition to superior cutting accuracy, our Precision Cutting Equipment also boasts a smaller heat-affected zone. By optimizing parameters such as laser power, spot size, and cutting speed, we are able to control the size of the heat-affected zone. This minimizes thermal impact on the surrounding area during the cutting process, reducing deformation, melting, and other forms of damage.

Another notable advantage of our Precision Cutting Equipment is its wider material applicability. With higher laser power and more working mode choices, our equipment is suitable for a wide range of materials. In addition to common metals and non-metal materials, our equipment is also capable of cutting more fragile materials such as glass, ceramics, and films while maintaining high precision and excellent cutting quality.

When it comes to cutting tasks that require high precision and fine structures, our Precision Cutting Equipment truly shines. With the ability to achieve narrower cutting widths, typically ranging from a few microns to tens of microns, our equipment is ideal for microelectronic device manufacturing, optoelectronic component processing, and other precision-driven applications.

Despite its emphasis on precision and fine cutting, our Precision Cutting Equipment doesn't compromise on production efficiency. Equipped with high-power lasers and high-speed motion systems, our equipment allows for quick completion of cutting tasks while maintaining the highest level of precision.

In conclusion, our Precision Cutting Equipment is a game-changer in the laser cutting industry. With its higher cutting accuracy, smaller heat-affected zone, wider material applicability, narrow cutting widths, and high production efficiency, our equipment is sure to exceed your expectations and elevate your cutting tasks to new heights. Experience the future of laser cutting with our Precision Cutting Equipment.

Product Specification Drawing

0102

Leave Your Message

0102