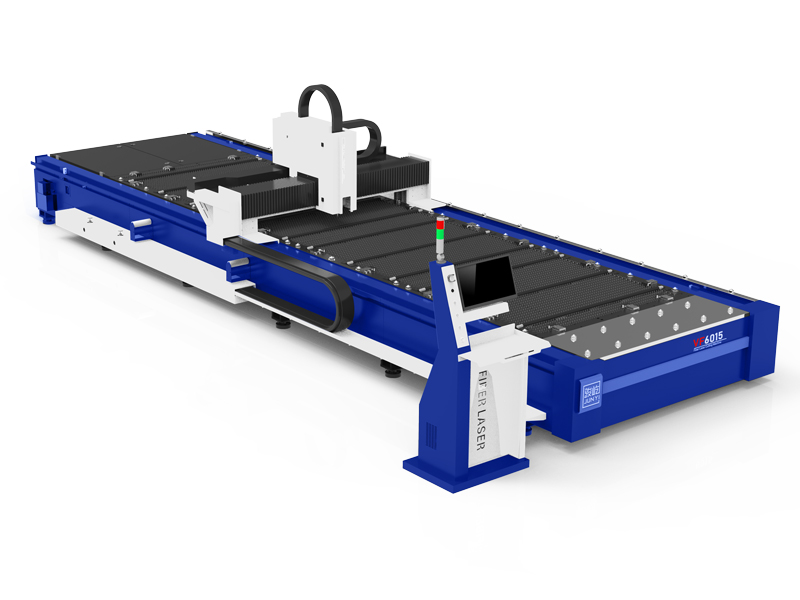

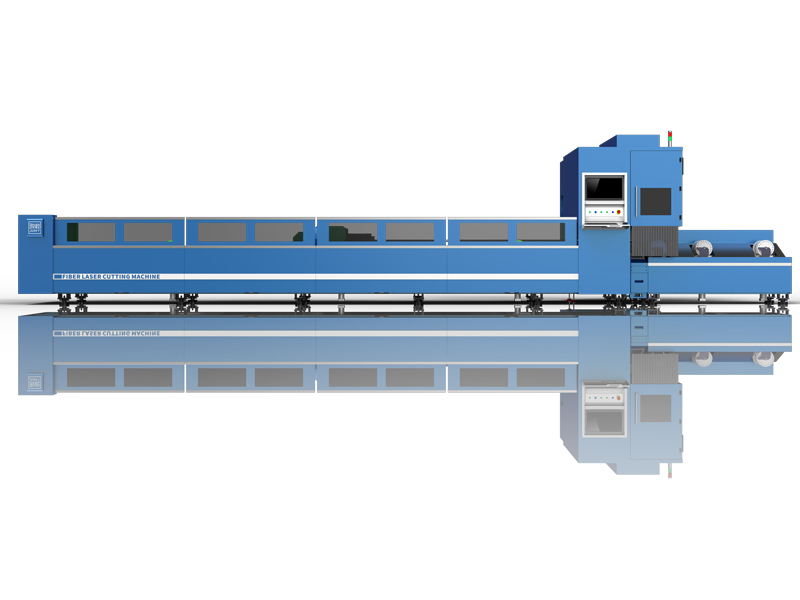

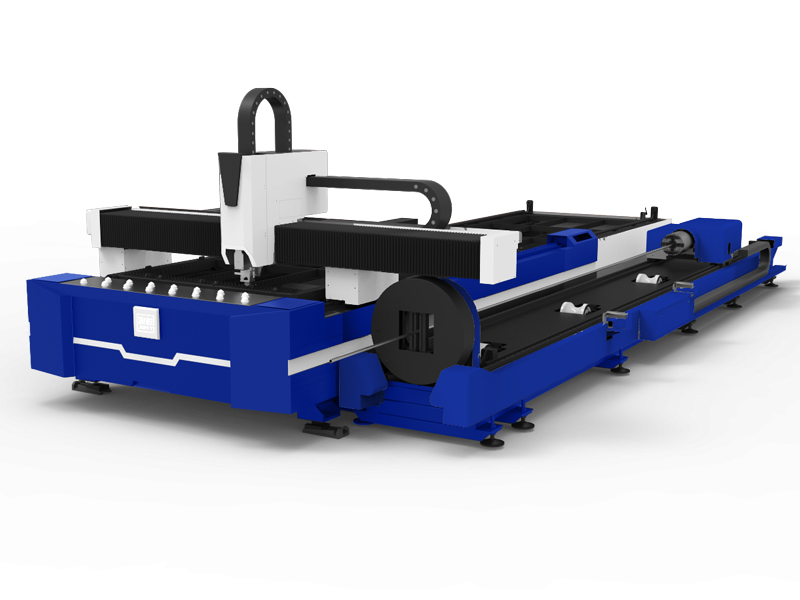

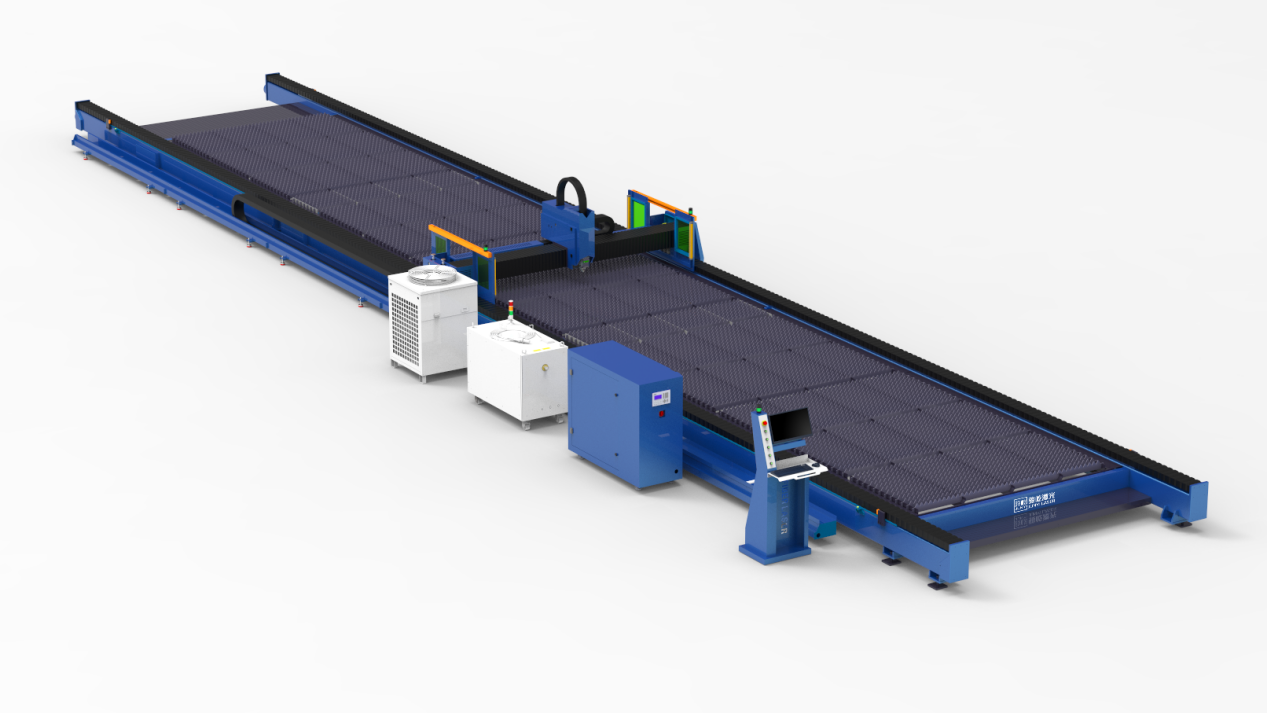

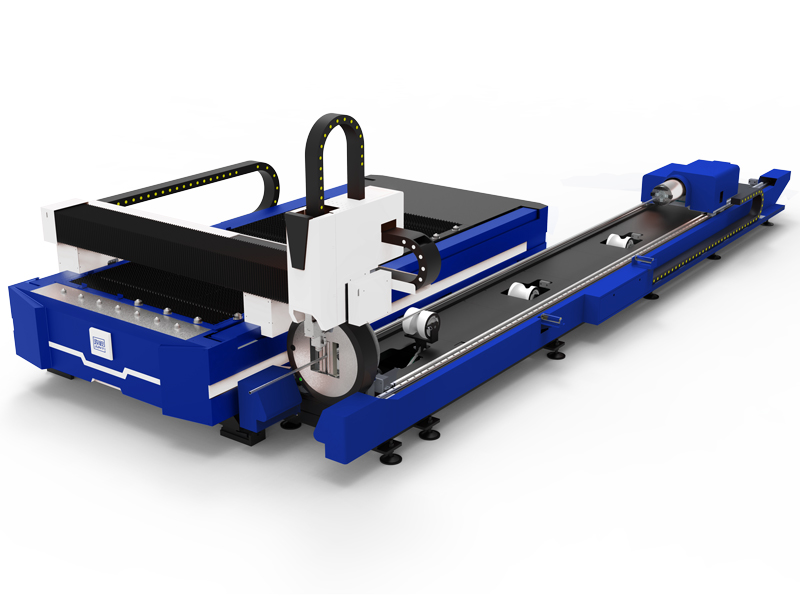

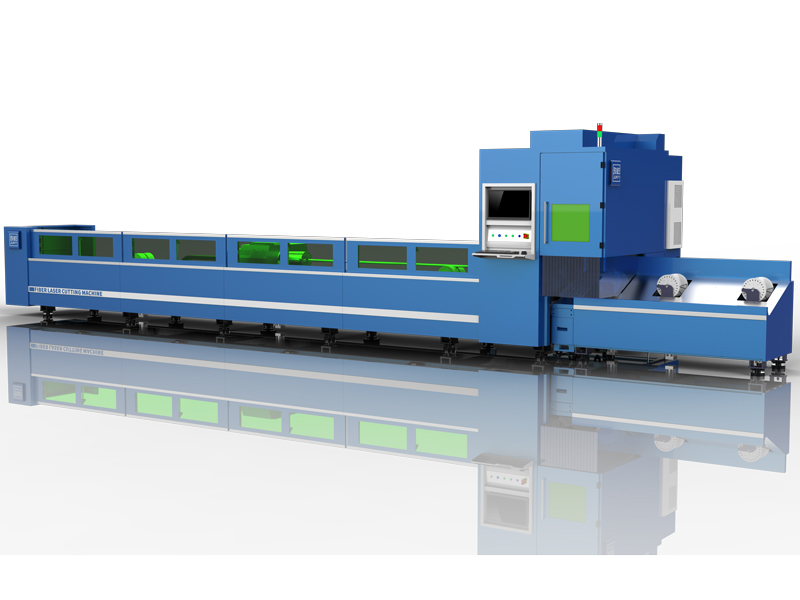

VF60G Fiber Laser Tube Cutter 1500-6000W

SPECIFICATIONS

Laser power |

3000W |

Loading method |

front and rear double pneumatic |

Chuck clamping diameter |

Φ20mm-Φ220mm |

Material type |

stainless steel round tube, square tube, rectangular tube, oval tube, etc. |

Pipe feeding length |

≤6000mm |

Laser cutting thickness |

stainless steel 10mm carbon steel 20mm |

Minimum tailing clamping length |

≤50mm |

Maximum single tube weight |

200KG |

X-axis working stroke |

0-200mm |

X-axis positioning accuracy |

±0.05mm |

X-axis maximum positioning speed |

60m/min |

X-axis repeatability |

±0.03mm |

Y-axis working stroke |

0-6050mm |

Y-axis positioning accuracy |

±0.05mm |

Y-axis maximum positioning speed |

80m/min |

Y-axis repeatability |

±0.03mm |

Z-axis working stroke |

0-250mm |

Z-axis positioning accuracy |

±0.05mm |

Z-axis maximum positioning speed |

35m/min |

Z-axis repeat positioning accuracy |

±0.03mm |

Technical parameter

LASERA MACHINE |

120mm chuck device |

220mm chuck device |

350mm chuck device |

Processing range |

Round tube: 15-120mm (diameter) |

Round tube: 15-220mm (diameter) |

Round tube: 15-350mm (diameter) |

Square tube: 15*15mm-105*105mm |

Square tube: 15*15mm-190*190mm |

Square tube: 15*15mm-300*300mm |

|

power |

3000W-6000W |

3000W-6000W |

3000W-6000W |

positioning accuracy |

±0.05mm |

±0.05mm |

±0.05mm |

Repeatability |

±0.03mm |

±0.03mm |

±0.03mm |

Shortest tail |

70mm |

70mm |

70mm |

Loading and unloading method: manual/automatic (optional) | |||

The cutting head is equipped with an automatic avoidance function, which can automatically recognize the pipe material and obstacles, enhancing processing safety. Furthermore, when processing shorter pipes, it can achieve independent clamping by the rear chuck, effectively reducing the length of cutting waste and improving pipe utilization.

Video

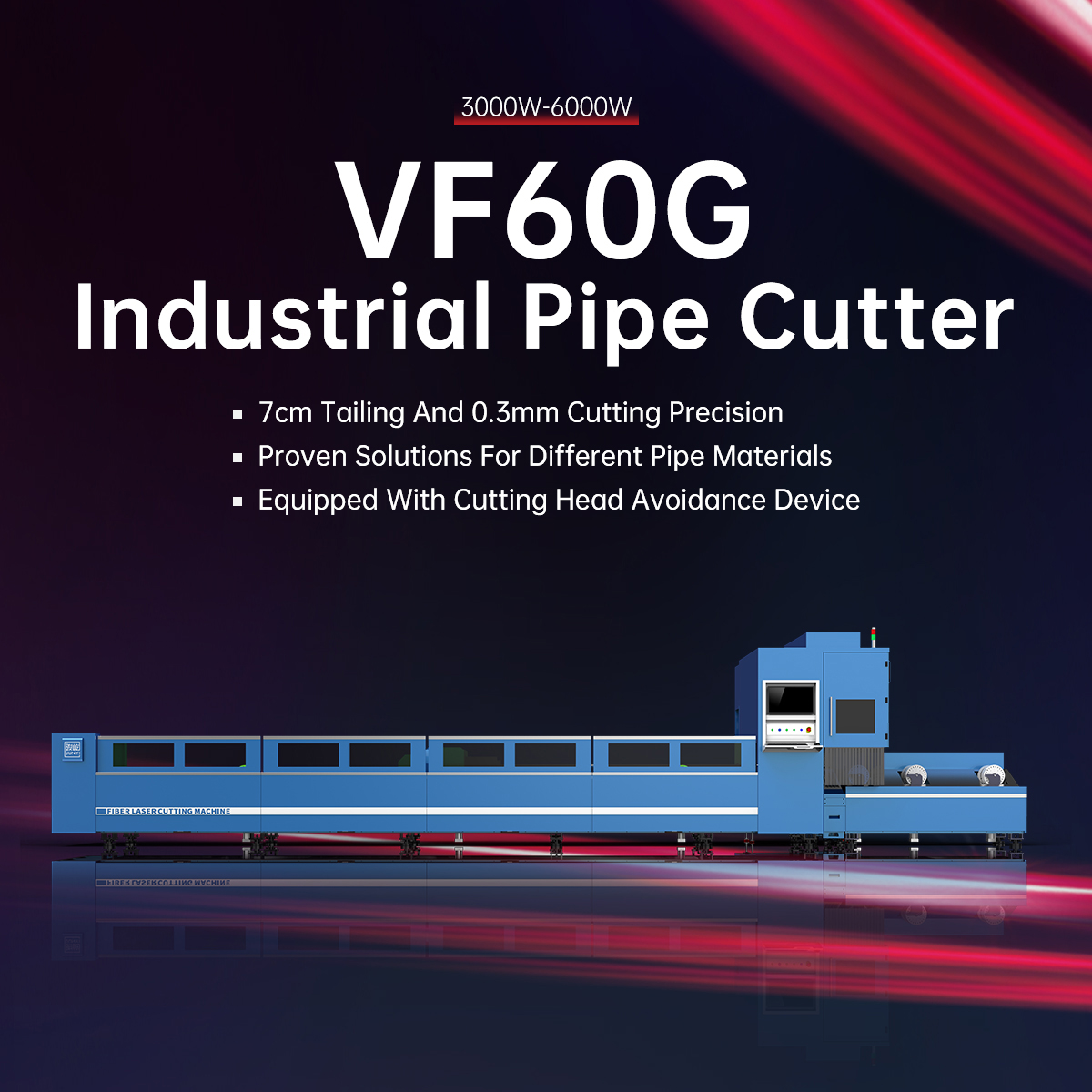

VF60G is your wise choice!

- Conventional technology

- Final accruacy ± 5 mm

-

14 minPlasma cutting

-

35 minGrinding

-

10 minHandling

- Lasertube technology

- Final accruacy ± 0.1 mm

-

4 min 50 secLaser cutting

- Conventional technology

- Final accruacy ± 2 mm

-

2 mincutting to size

-

35 minGrinding

-

10 minHandling

- Lasertube technology

- Final accruacy ± 0.1 mm

-

1 minLaser cutting

- Conventional technology

- Final accruacy ± 3 mm

-

3 minmilling to size

-

35 minGrinding

-

12 minLogistic

- Lasertube technology

- Final accruacy ± 0.1 mm

-

8 min 20 secLaser cutting