0102030405

How to set the processing parameters for cutting carbon steel and stainless steel plates at 6KW and 12KW?

2024-04-30 13:46:32

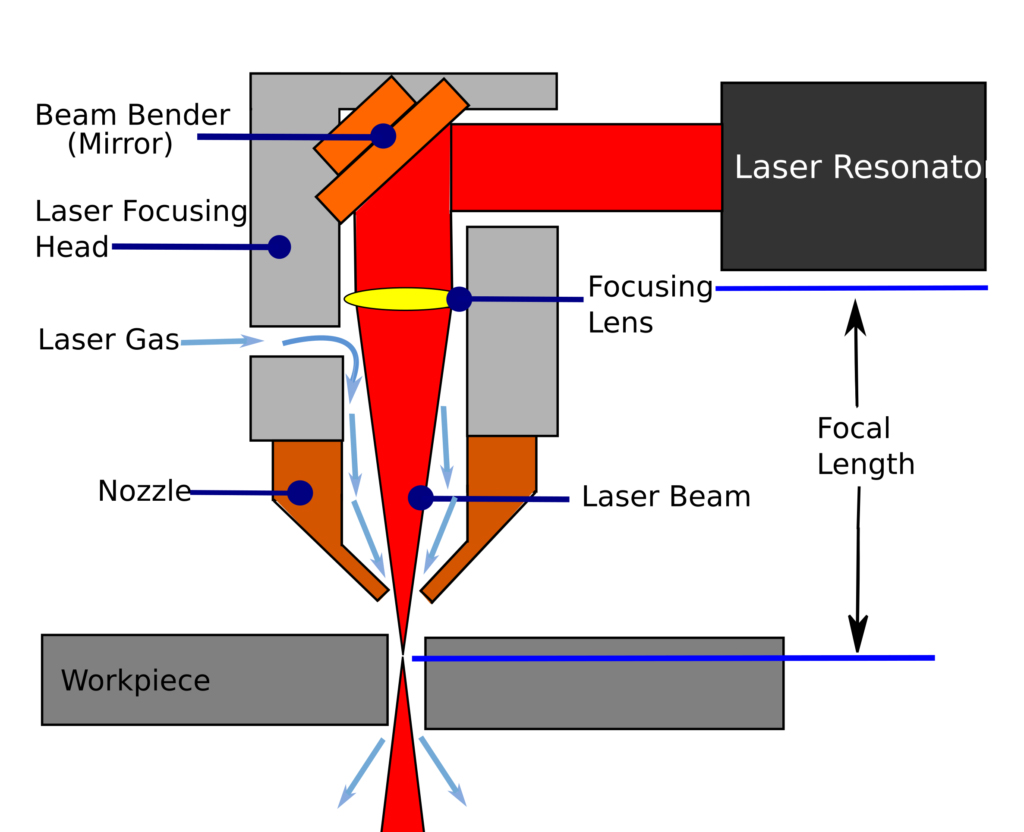

When using equipment with a power of more than 6000W, cutting thick plates of carbon steel of more than 25mm, cutting relatively complex small holes and other patterns, high focus and full power are required to achieve stable production.

Cutting parameter characteristics:

1. The cutting head does not get hot when the focus is the highest focus.

2. Cutting carbon steel above 25mm

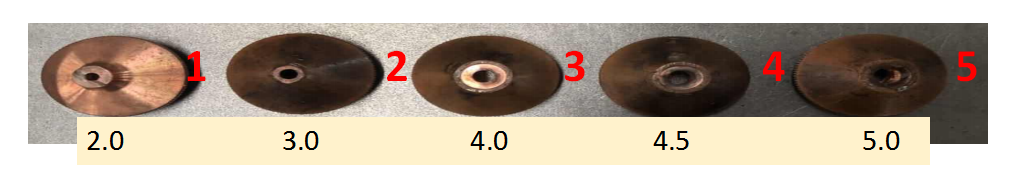

3. Use fast nozzle 1.6-1.8 or ordinary 2.0 double-layer nozzle for cutting

4. The cutting speed is slow and cannot be improved.

5. The air pressure is set to 0.7-1.0bar, and the nozzle height is 0.8-1.0bar.

When cutting carbon steel and stainless steel, if sparks are concentrated and there are no scattered or tilted sparks around, the quality of the cut section is excellent. If two kinds of sparks appear, it means there is a problem with the cutting parameters and needs to be adjusted. If there are light yellowish and reddish sparks around the cutting stainless steel, it means The focus is too low and with the generation of plasma, the cutting surface is poorly delaminated.

Cutting effect of stainless steel material:

There is white light in the lower area that has not been cut through, and the focus moves downward.

There is hard slag in the lower area, and the focus moves downward

There is a black border mark on the lower surface, indicating high power or slow speed.

Granular soft slag on the lower surface, increase speed or reduce air pressure

35mm stainless steel debugging - basic parameters

| Thickness(mm) | Power(w) | Speed(m/min) | Focus(mm) | Nozzle(mm) |

| 35mm | 12000 | 0.2 | 8 | No.3 |

| Nozzle height | Pressure(w) | Frequency(HZ) | Duty ratio% | - |

| 0.5 | 18bar | 200 | 55 | - |

Single nozzle type

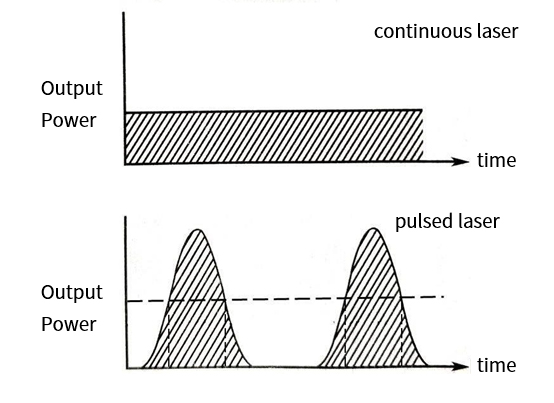

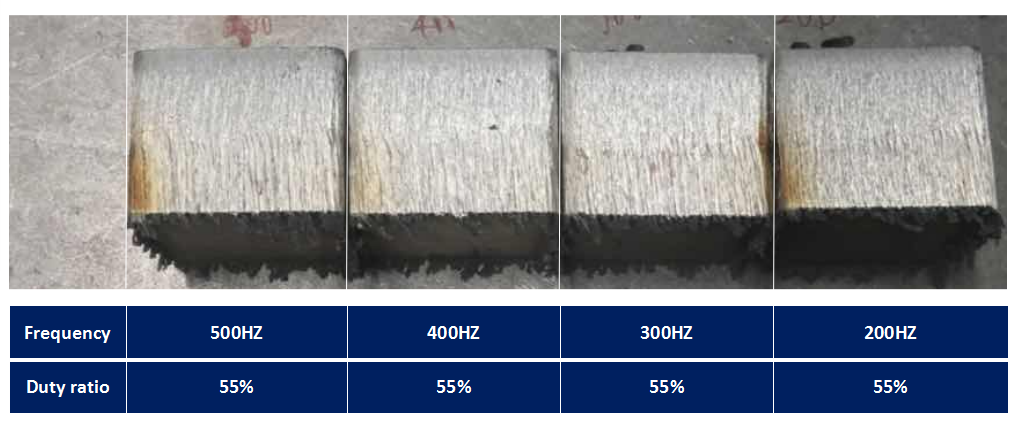

Frequency and duty ratio

| POWER | HZ | DUTY% | single pulse power | single pulse times | pulse stop time(ms) |

| 12KW | 500 | 55 | 13.2 | 500 | 0.9 |

| 12KW | 400 | 55 | 16.5 | 400 | 1.125 |

| 12KW | 300 | 55 | 22 | 300 | 1.5 |

| 12KW | 200 | 55 | 44 | 200 | 2.25 |

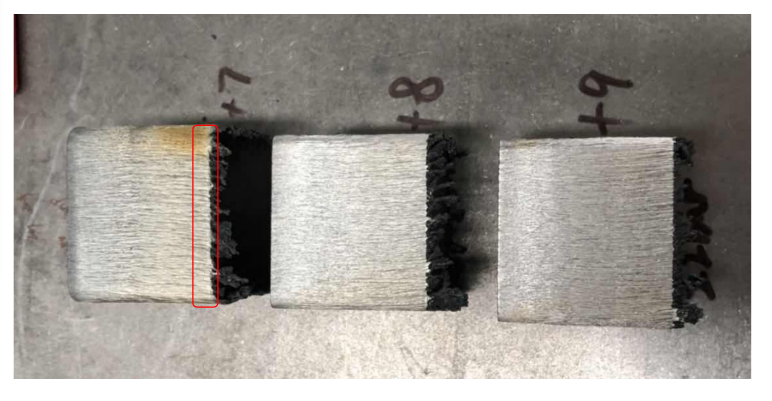

Figure 1: Cutting comparison, other parameters remain unchanged, change the frequency, 500~200 frequency, the cutting section effect is gradually improved in layers. When the frequency is set to 100, the cutting anti-blue light, the duty cycle remains unchanged, the frequency becomes smaller and the section gradually improves. , individual lasers have differences, and the trend is consistent.

To ensure the quality of the section, according to the values in the table above, the principle of normal focus cutting limits the speed increase. The power and speed are not in a doubling relationship, and the actual speed is basically the same.

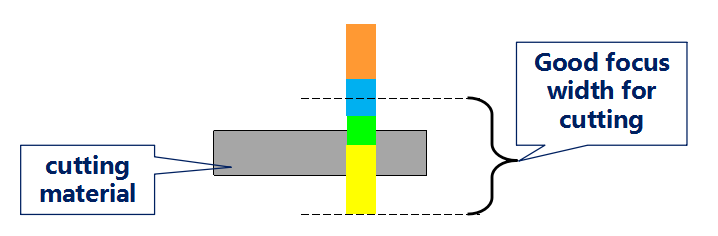

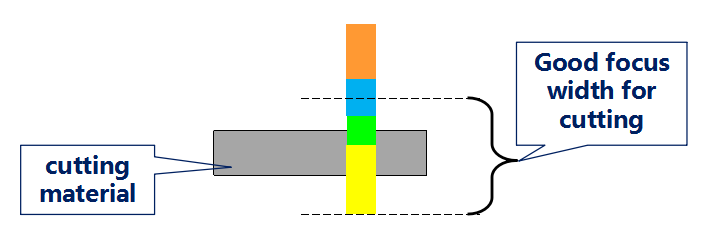

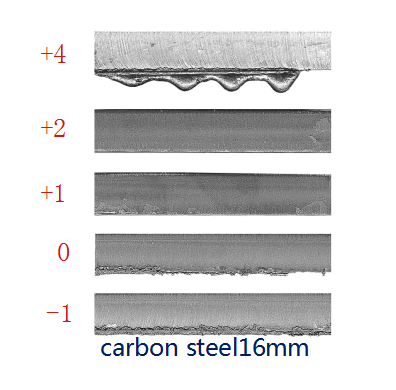

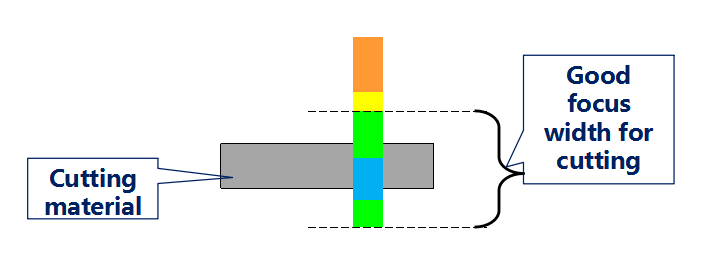

Affected by focus changes, focus +7 appears to be delaminated in the lower section. As the focus rises, the uncut traces on the lower surface are reduced and the delamination is reduced. The focal width is about 2mm. Continue to rise. Focus +10 reflects blue light. Through the offset of the focus, find out Best face focus position.

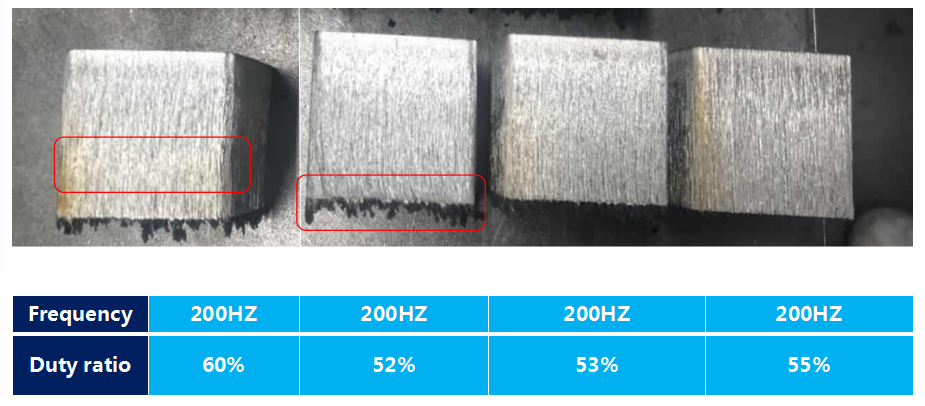

Influenced by changes in duty cycle, 53% is the critical value. If the duty cycle is reduced further, uncut traces will appear on the surface. As the duty cycle slowly increases, the delamination will become more obvious and the cross-section will become worse.