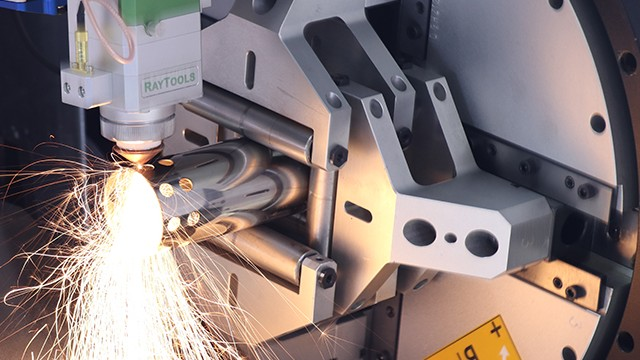

Introducing the Laser Pneumatic Chuck: Revolutionizing Small Tube Cutting

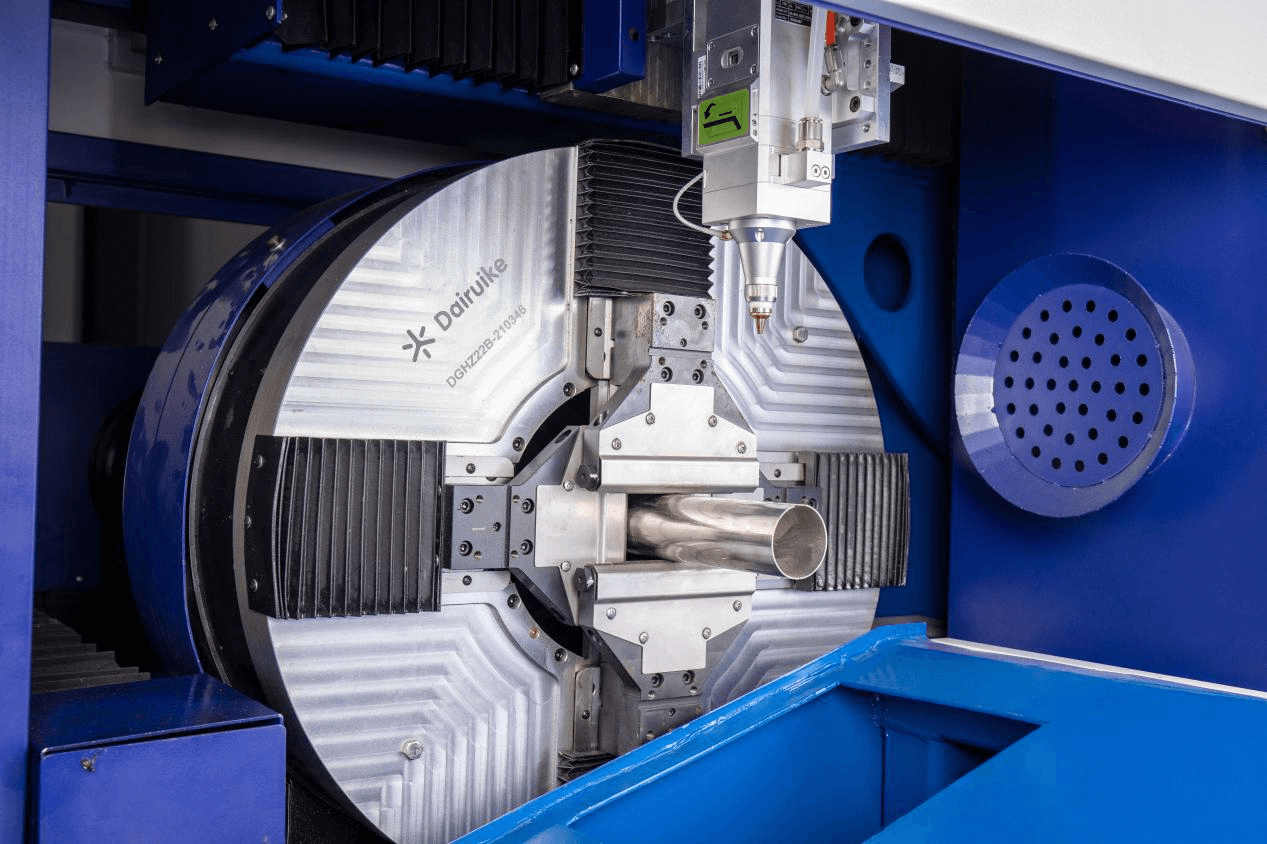

In the world of small tube cutting, efficiency, precision, and cost-effectiveness are paramount concerns for industries such as furniture, medical equipment, and display props. However, a game-changing solution has emerged in the form of the laser pneumatic chuck, offering a myriad of advantages that address the challenges faced in small tube processing.

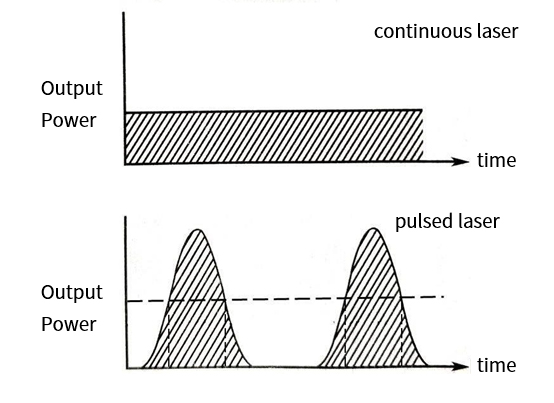

One of the key advantages of the laser pneumatic chuck is its small inertia and fast speed. With an acceleration reaching an impressive 1.2G, it enables lightning-fast processing, exceeding expectations in real-world scenarios. For instance, in a terminal requiring 2,000 pieces to be cut per day, the laser pneumatic chuck has demonstrated the capability to cut 2,500 pieces, showcasing its remarkable speed and efficiency.

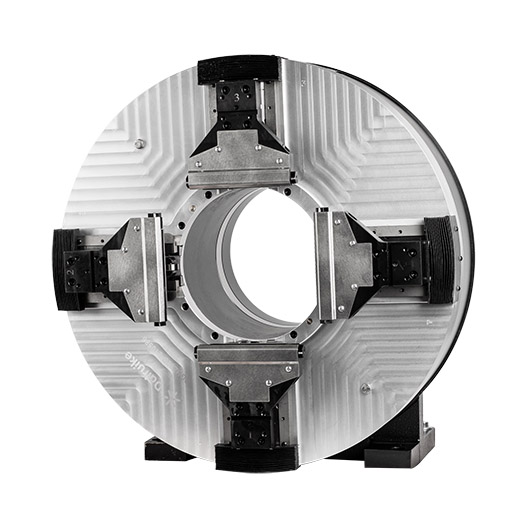

Moreover, the laser tube cutting machines equipped with the pneumatic chuck offer a processing range of 10-120mm, providing flexibility without being constrained by the size of small tubes. This versatility makes it an ideal choice for a wide range of tube processing industries, including medical equipment, display furniture, office furniture, and auto parts.

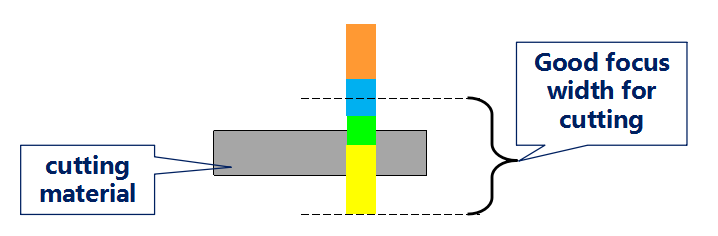

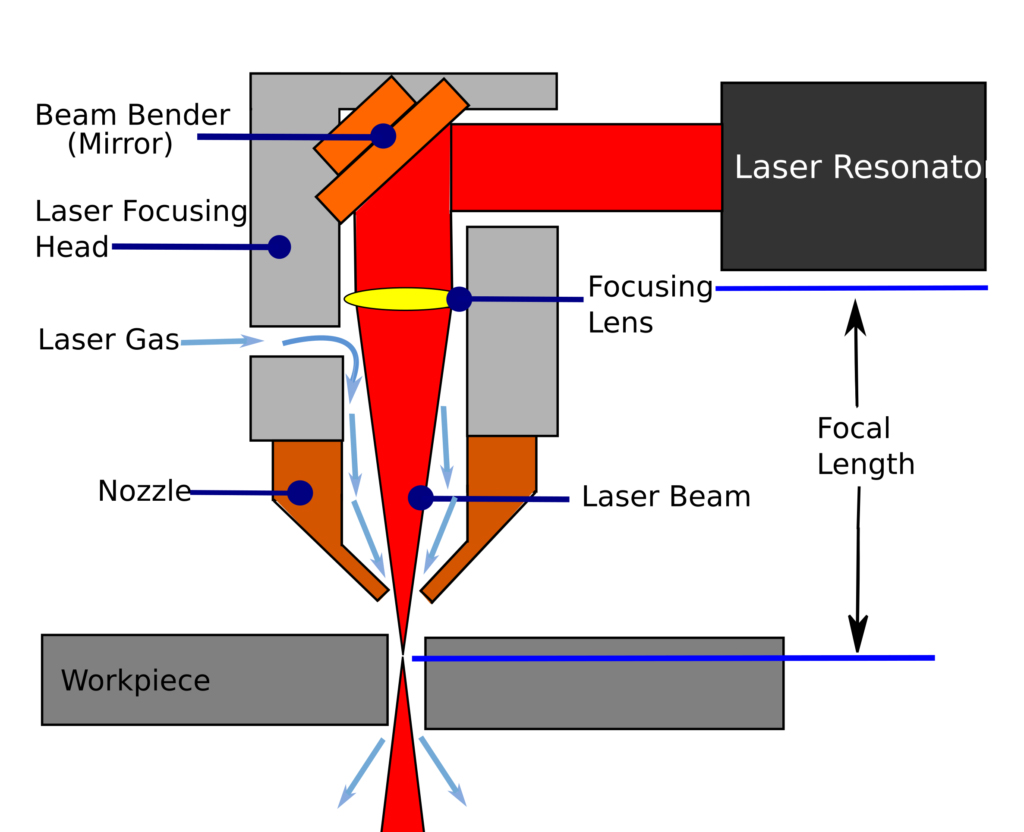

In addition to speed and flexibility, the laser pneumatic chuck delivers high precision, stability, and material-saving capabilities. Its full-stroke clamping, automatic and precise centering, and stable opening and hanging in fast cutting state ensure a level of precision that is crucial for industries requiring intricate and accurate tube cutting.

Furthermore, the laser pneumatic chuck is designed to be extremely material-saving, with features such as less remaining material and controllable tail material, significantly improving the utilization rate of the pipe. This not only contributes to cost savings but also enhances the overall efficiency of the cutting process.

Compared to manual chucks, the pneumatic chuck offers unparalleled convenience and cost-effectiveness. With the ability to automatically center and clamp the workpiece at the press of a button, it provides stable and reliable clamping force while allowing for size adjustments. This not only enhances work efficiency but also reduces human resource costs and minimizes the need for fixed equipment investment, making it an attractive option for mechanical processing enterprises dealing with batch pipe fittings.

In conclusion, the laser pneumatic chuck has emerged as a game-changer in the realm of small tube cutting, offering a compelling combination of speed, precision, material-saving capabilities, and cost-effectiveness. Its impact is poised to revolutionize the small tube processing industry, providing a competitive edge to businesses seeking to enhance their cutting operations.