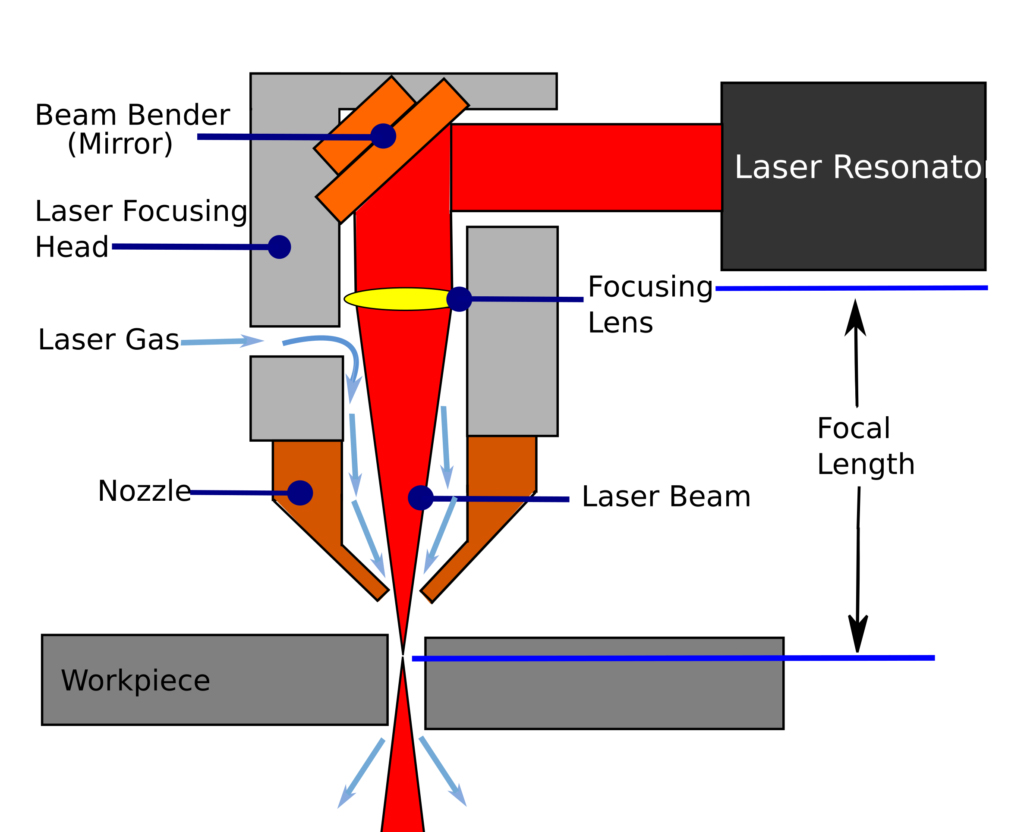

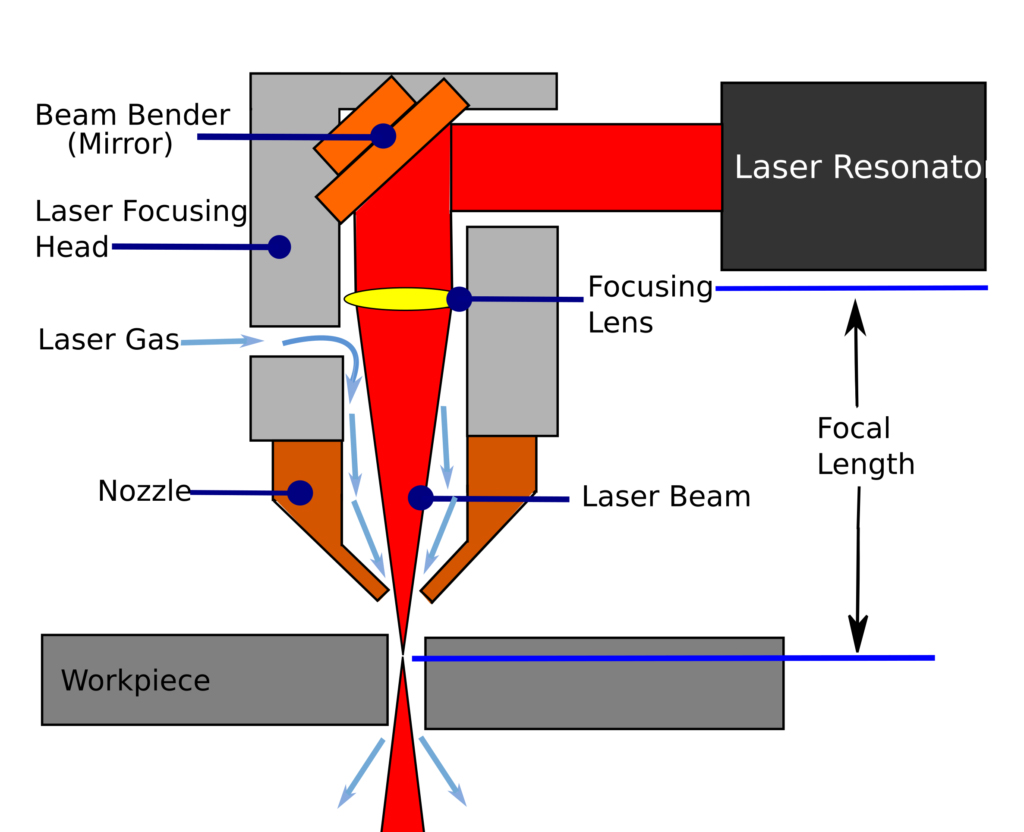

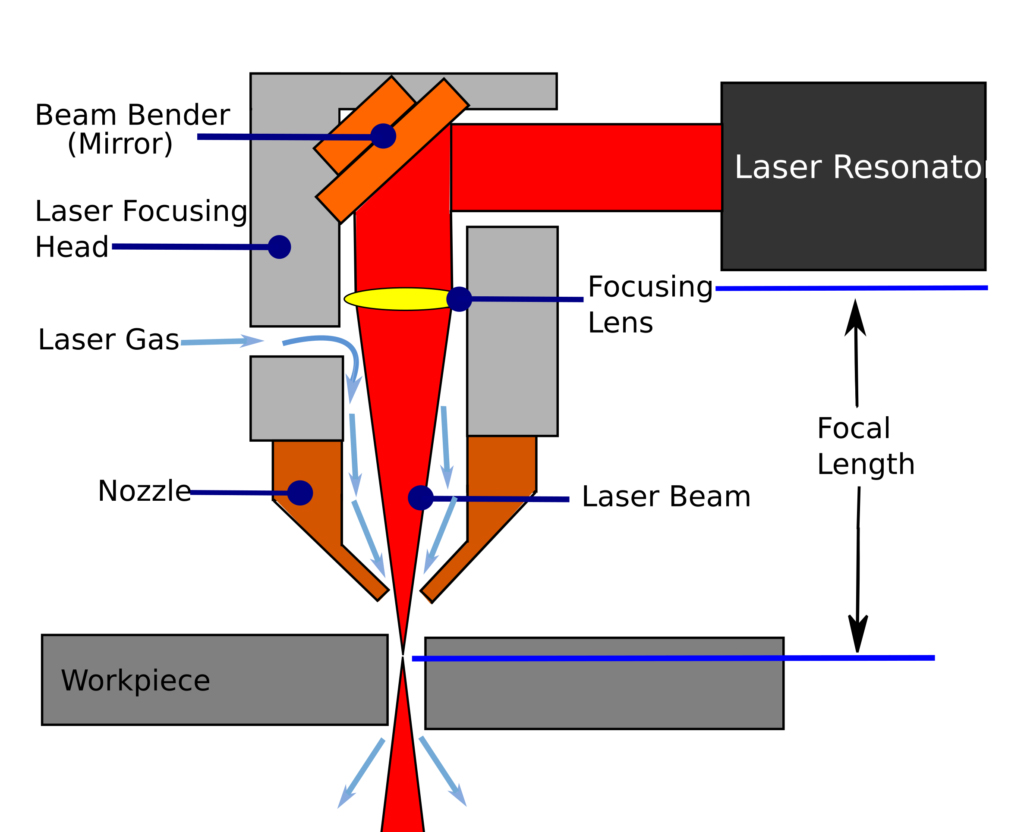

The simple schematic diagram of laser cutting is shown in the figure below. During the process, auxiliary gas needs to be used to blow away the slag in the cutting seam, cool the surface of the processed object to reduce the heated area, and cool and protect the lens of the laser head. Auxiliary gases generally include oxygen, nitrogen, compressed air, etc., which directly affect cutting performance, cutting speed, cutting thickness, etc. Different auxiliary gases need to be used according to the differences in cutting materials.

1. Oxygen as auxiliary gas

Oxygen is often used to cut thicker carbon steel materials. Because the heat of chemical reaction with iron elements will promote endothermic melting of the metal, it can greatly improve cutting efficiency. However, oxygen will cause the material to be cut to produce an obvious oxide film on the end surface of the cut, and will also produce a quenching effect on the material around the cutting surface, increasing the hardness of this part of the material, which will have a certain impact on subsequent processing. The cut end of oxygen-cut materials turns black or dark yellow. Generally, carbon steel plates are cut using oxygen, low-pressure drilling, and low-pressure cutting. Oxygen is generally vaporized from liquid oxygen provided by air separation plants, so the quality of the gas source is clean and no special treatment is required.

2. Nitrogen as auxiliary gas

When nitrogen is used as an auxiliary gas for cutting, it will form a protective atmosphere around the molten metal to prevent the material from being oxidized, avoid the formation of oxide films, and achieve oxidation-free cutting of the material. However, the cutting ability is not as good as that of oxygen, and the nitrogen consumption of nitrogen cutting is larger, and the cutting cost is higher. The non-oxidized cutting surface has the characteristics of direct welding, painting, strong corrosion resistance, etc., and the cut end surface is white. Nitrogen gas is generally used to cut stainless steel, galvanized sheets, aluminum and aluminum alloys, brass and other materials, using low pressure to pierce and high pressure to cut. During nitrogen cutting, changes in gas flow have a great impact on cutting. While ensuring the cutting gas pressure, sufficient gas flow must be ensured. Nitrogen is generally vaporized from liquid nitrogen provided by air separation plants, so the quality of the gas source is clean and no special treatment is required.

3. Compressed air as auxiliary gas

Compressed air is easier to obtain than oxygen and nitrogen and is very cheap. Air contains about 20% oxygen and about 78% nitrogen. The cutting efficiency is far lower than that of oxygen cutting, but the cutting ability is close to that of nitrogen. The cutting efficiency of air is slightly higher than that of nitrogen cutting. Due to the presence of oxygen, the cut end surface turns yellow. When there are no strict requirements on the surface color of the material incision, using compressed air instead of nitrogen cutting is the most economical and practical choice. It is generally used for cutting sheet metal parts, aluminum plates, non-metallic and galvanized sheet materials. To a certain extent, it can reduce oxidation. Membrane and cost-saving, it is one of the cutting gas sources that is increasingly used.

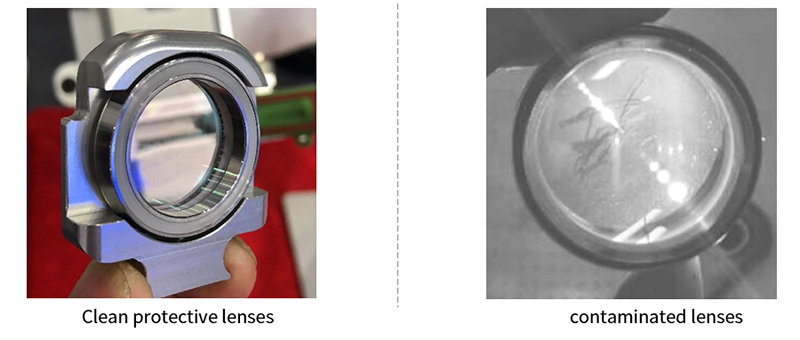

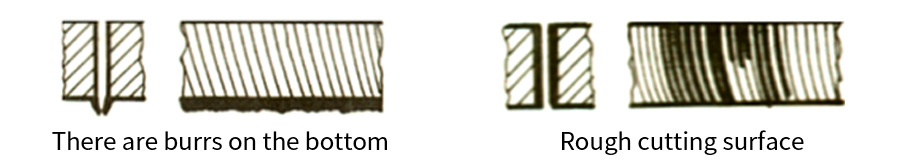

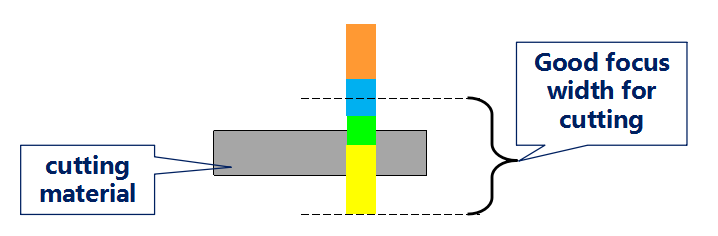

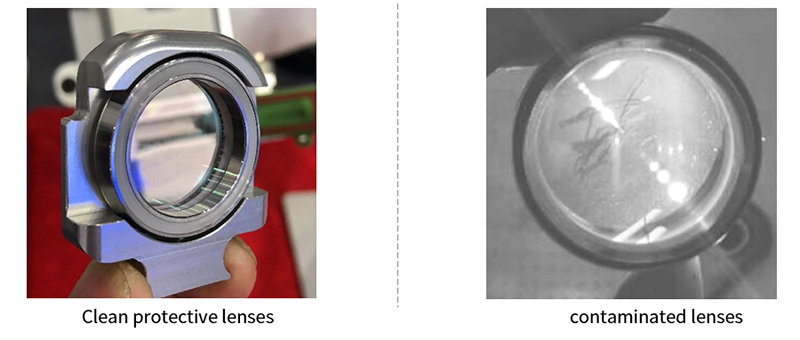

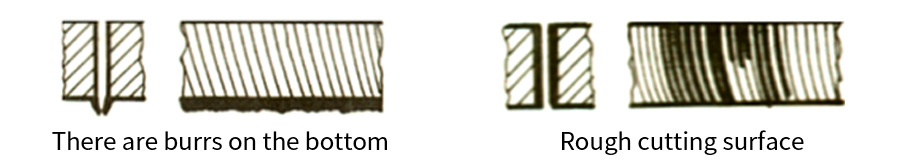

Compressed air can be obtained directly from an air compressor, but the air itself is not clean. The compressed air contains a large amount of water, oil, particulate matter and other pollutants. If the compressed air is impure, high pressure will be sprayed onto the protective mirror of the laser cutting head. , will contaminate the protective lens (as shown in the picture), seriously affect the transmission of the laser beam, disperse the focus, cause the product to be unable to cut through, easily have burrs (as shown in the picture), and the cutting surface is rough (as shown in the picture), and even produce waste products. If it is a high-power laser cutting machine, as long as there is a very fine oil film or water mist on the protective mirror or nozzle surface, it may cause high-energy laser emission to burn out the laser head.

Therefore, continuous and stable clean compressed air is needed to ensure the cutting effect and protect the laser cutting machine from damage. At present, the indicator that gas applications in this industry can meet the requirements (classified according to ISO 8573-1-2010) is that the pressure dew point is not less than level 5 (3~7℃) (in general, the working conditions when the temperature is the highest all year round should be considered. In addition, the northern In areas where the temperature is below zero, if the pipeline is outdoors or is long, the impact of temperature on the compressed air must be considered), the particulate matter content is not less than level 2, and the total oil content is not less than level 2 (<0.1mg/Nm³, containing oil steam part).