Driving Industrial Upgrading, Chuangxin Laser Injects Strong Power into the Development of Metal 3D Printing

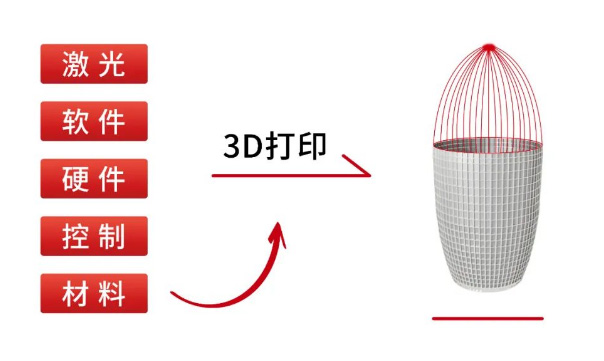

Laser 3D printing is a systematic and comprehensive technology that integrates multiple disciplines such as laser, computer software, materials, machinery, and control. This approach completely changes the traditional processing mode of metal parts, especially high-performance, difficult-to-process, and complex-shaped metal parts.

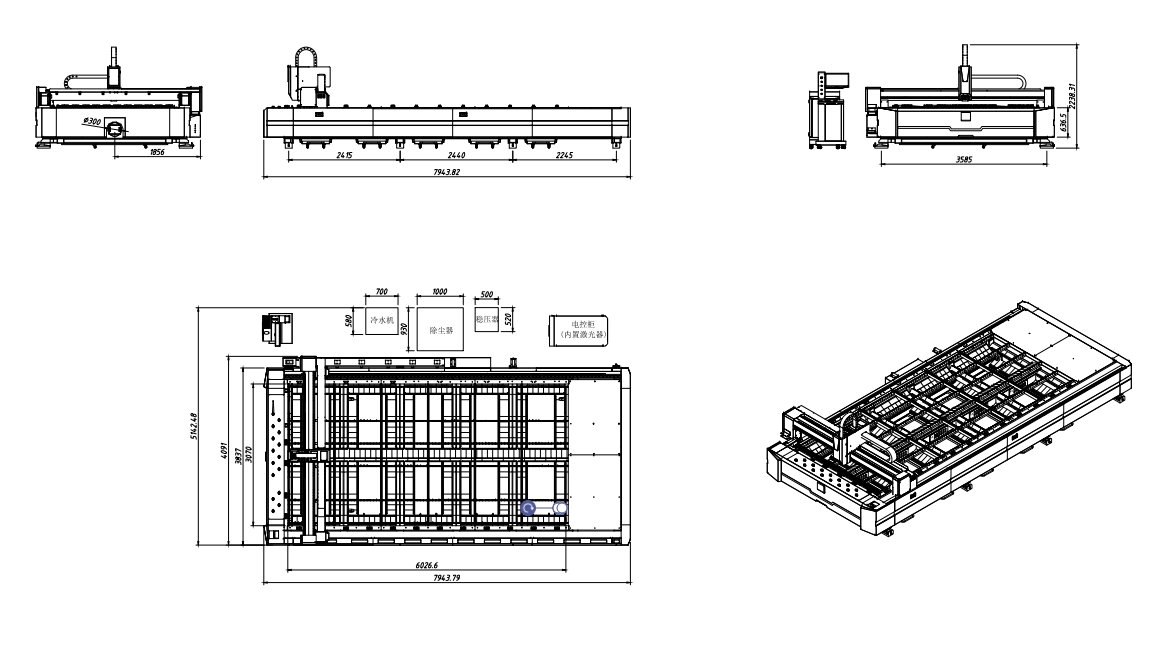

Currently, there are two typical methods for laser metal 3D printing: Selective Laser Melting (SLM) based on powder bed and Laser Engineered Net Shaping (LENS) based on synchronized powder feeding. The laser power used in these two methods is mostly between 300-1000W/3000-6000W.

As the power source in the printing equipment, lasers have high performance requirements, including power and energy density, stability and consistency, wavelength, beam quality, adjustability, and durability.

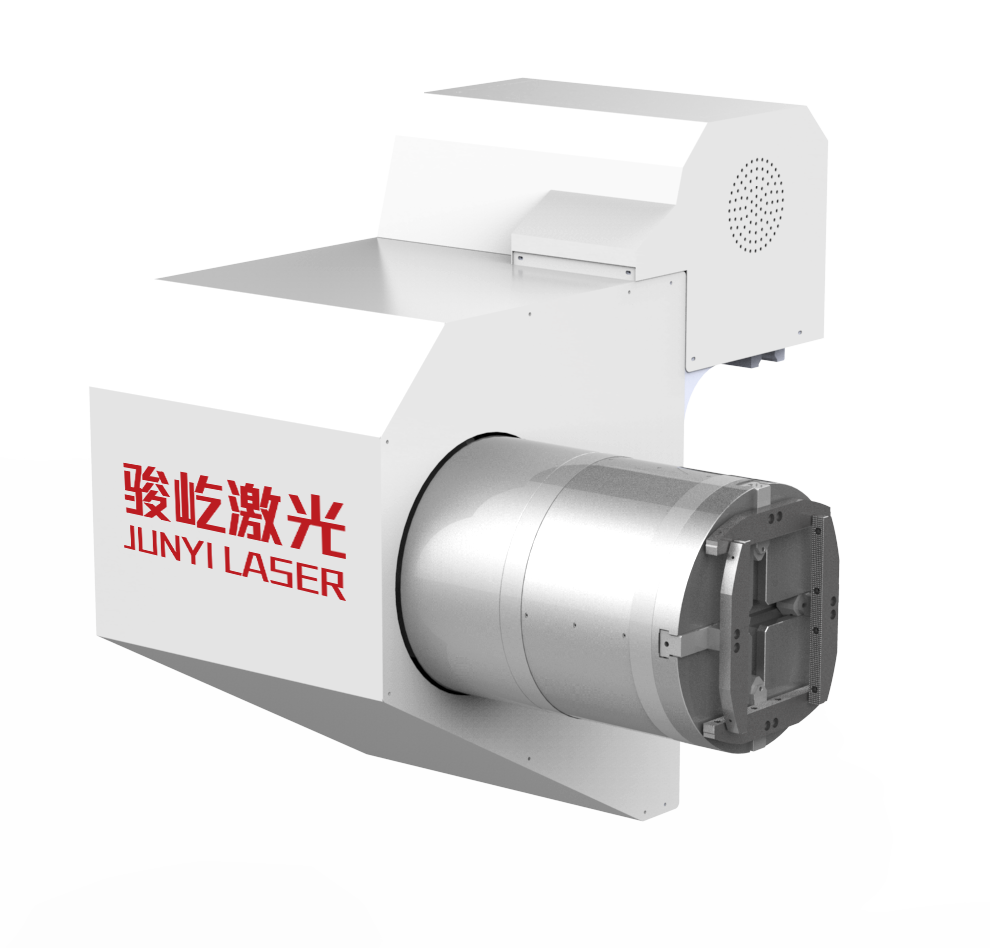

Different from conventional lasers, Chuangxin’s 3D printing industry-specific lasers are more in line with the requirements of 3D printing. By combining advanced optical technology and stable power output, they have the following outstanding features:

Multiple power options: The specialized lasers provide multiple power options, including 300/500/1000W, ring-shaped beam 1000/2000W, and multimode 6000/12000W, which can meet the application needs of different customers and support the printing of large structural parts and complex details.

Stable and consistent output: The specialized lasers have stable power output, with short-term power stability within 1% and long-term power stability within 2%, ensuring reliable and high-quality melting and solidification during the printing process. At a customer’s site, it can run continuously for more than 60 hours in a single operation, and the product has a stable working lifespan of 5 years.

High beam quality: The specialized lasers have excellent beam quality and beam focusing ability, with a beam quality of less than or equal to 1.1, ensuring rapid melting and fusion of metal powders, resulting in higher printing resolution and finer details.