Importance of Laser Chuck Maintenance for High-Quality Pipe Cutting Machines

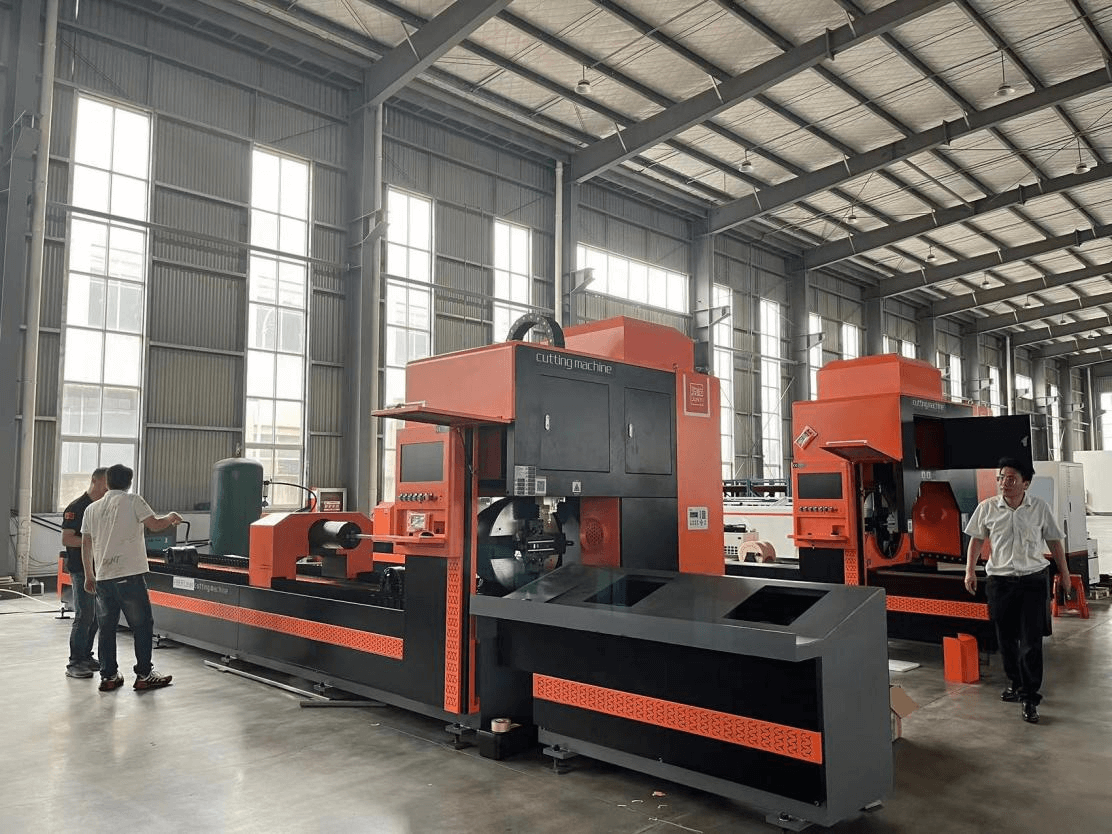

In the realm of manufacturing technology, the significance of regular maintenance for high-quality pipe cutting machines cannot be overstated. Among the various components of these machines, the laser chuck holds a pivotal role in ensuring the normal operation of the equipment and achieving high cutting results. Therefore, it is imperative to understand the different aspects of laser chuck maintenance to uphold the efficiency and precision of these machines.

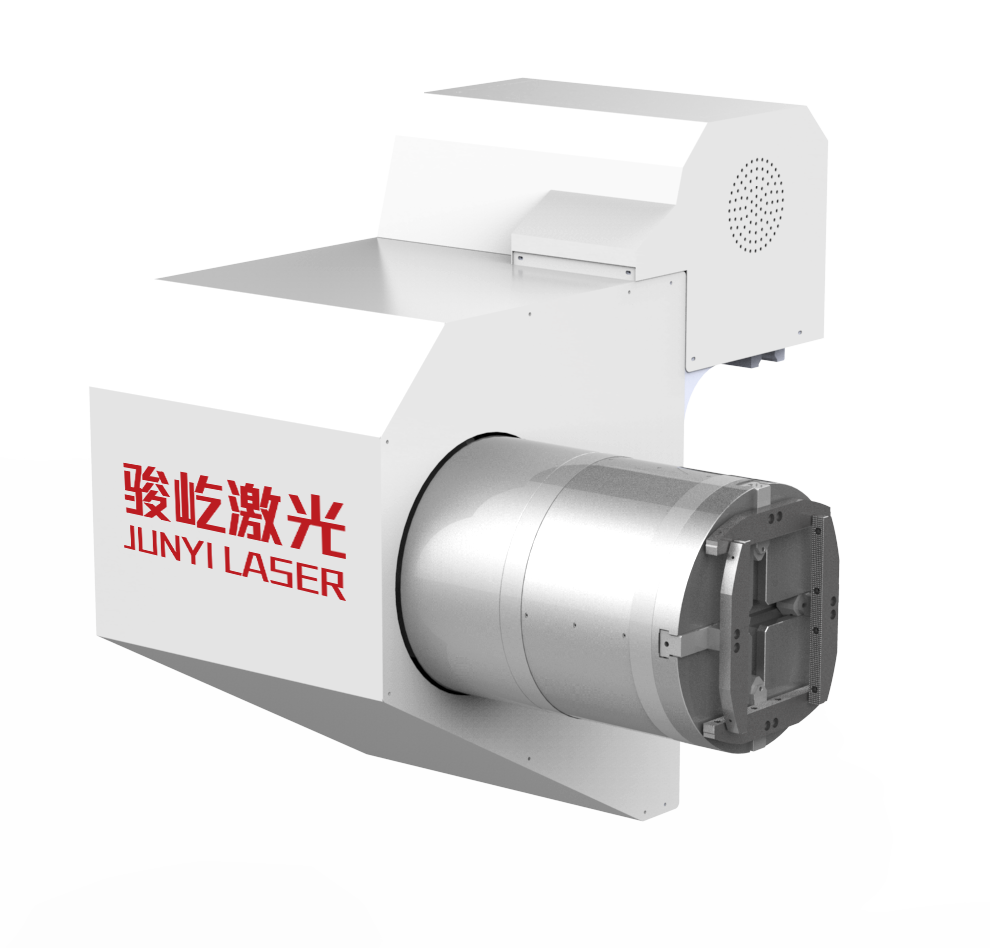

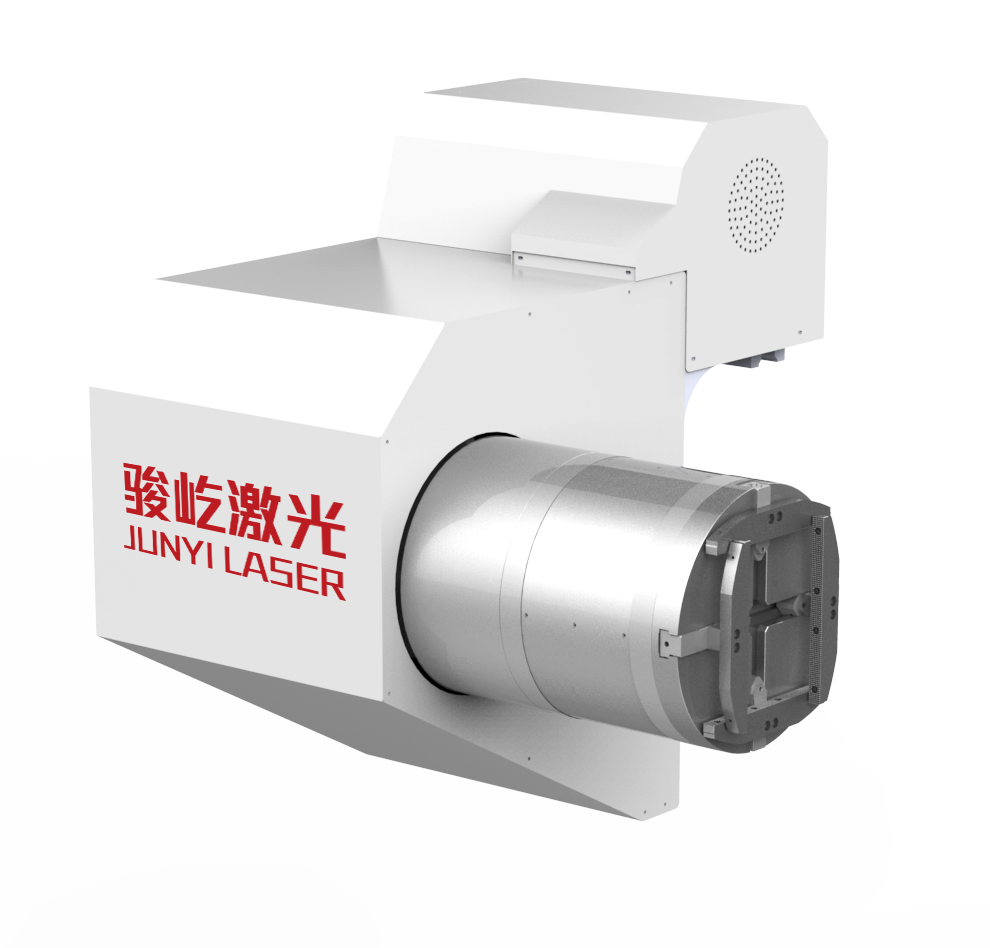

First and foremost, the clamping methods employed for different workpieces play a crucial role in the maintenance of laser chucks. It is essential to utilize appropriate clamping methods or create specialized clamps to accommodate workpieces with irregular shapes. Failure to do so may lead to chuck abnormalities, hindering the overall performance of the machine. However, with the Dairic laser chuck, automatic and accurate centering capabilities, along with stable and reliable holding force, enable it to effectively clamp round tubes, rectangles of various specifications, pipe, channel steel, I-beam, angle steel, special-shaped pipe, and more.

Another vital aspect of laser chuck maintenance involves the use of molybdenum disulfide grease, which is black in color. This grease should be carefully applied to the chuck lubrication nozzle, ensuring that it overflows the jaw surface or inner hole of the chuck. In cases where the laser metal pipe cutting machine operates at high speeds for extended periods or processes large amounts of oxygen, additional lubrication becomes necessary to uphold the chuck's performance. Adhering to the specific lubrication frequency outlined in the machine's instructions is crucial for optimal maintenance.

Lubricating oil also plays a significant role in maintaining the chuck. Proper lubrication ensures accuracy even with prolonged usage. However, it is essential to note that incorrect or inappropriate lubrication can lead to various issues, such as the pneumatic chuck malfunctioning under low air pressure, weakened clamping force, poor clamping accuracy, abnormal wear, and more. Therefore, adhering to the prescribed lubrication operations is imperative to prevent such complications and maintain the chuck's functionality.

Furthermore, preventing rust is a critical aspect of laser chuck maintenance. Rust can significantly impede the clamping force of the chuck, leading to its inability to effectively clamp workpieces. This interference can weaken the overall performance of the machine. Therefore, implementing measures to prevent rust and regularly inspecting the chuck for any signs of corrosion are essential maintenance practices.

In conclusion, the maintenance of high-quality pipe cutting machines, particularly the laser chuck, is vital for ensuring optimal performance and high cutting precision. By addressing the various aspects of laser chuck maintenance, including appropriate clamping methods, lubrication, and rust prevention, manufacturers can uphold the efficiency and reliability of their equipment, ultimately contributing to enhanced productivity and quality in the manufacturing process.