How to make full use of a normal fiebr laser cutting machine?

Everyone knows the importance of a useful machine for modern production, but there’s a small group of people really know how to make full use of the tool.

There’s no doubt that a fiber laser cutting machine could cut different kinds of metal materials with fast speed and relatively great precision. That’s the reason why customers favor those factories with a set of fiber laser equipment.

And do you know how to optimize the cutting effect with the help of parameter settings?

Considering that Cypcut control system occupied the majority of fiber market, the following content would be introduced based on the operation of Cypcut software.

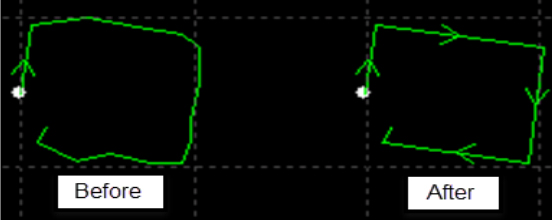

Cypcut software will automatically optimize the file under Home-Optimize menu, users could manually select the optimize options. If you want to smooth the graphic or line, you could select the poly line and dialog box, and then input the smooth button.

The smooth reuslt shown below.

When it comes to the cutting technique, you may use most of the function under “Technical parameter” column in the Home menu bar, including setting lead lines and compensations, etc.

The large size button “Lead” used to set lead lines, and the button “Seal” used to set the over-cut, gap or seal parameters. The button “Compensate” is used to set compensation. The button “Micro Joint” is used to set a micro-joint that will not be processed on the object. The button “Reverse” is to reverse the machining direction of a single object selected. The button “Cooling point” is to set the cooling point.